Researchers at the Skolkovo Institute of Science and Technology (Skoltech) have utilized a novel 3D printing technique to manufacture a highly complex ceramic part that could be used in environmentally-friendly solid-oxide fuel cells (SOFCs).

The research team utilized a cost-effective combination of micro-stereolithography technology and a common office projector to produce the SOFCs, which incorporate a new hierarchical lattice structure. This 3D printed lattice enhances the ionic conductivity of the fuel cells, maximizing their power output. This is said to be key to accelerating their adoption in various verticals including transportation and industrial power generation.

Having been optimized in a lab setting, the focus will now switch to creating a one-off functional SOFC prototype which incorporates the complex 3D printed lattice structure.

According to the study, published in the journal Ceramics International, this structure cannot be fabricated using traditional manufacturing techniques

“We have shown that 3D printing, and the inexpensive micro-stereolithography setup in particular, can actually produce complex structures from one experimental and one commercial-grade material used in emerging solid-oxide fuel cells,” commented Skoltech MSc alumnus Igor Pchelintsev, the study’s lead author. “This is a step toward improving the efficiency of fuel cells to the point where they could compete with and phase out dirtier energy sources.”

In September 2022, The US Department of the Treasury commenced sanctions against the Skolkovo Foundation, the Skolkovo Institute of Technology, and Technopark Skolkovo.

SOFCs: a sustainable energy alternative

SOFCs offer a more sustainable and environmentally friendly alternative to burning natural gas or other fossil fuels at power plants or in combustion engines. These fuel cells can generate electricity for industrial facilities or homes, and are ideal for generating energy for remote off-grid locations, boats, cars, and satellites.

SOFCs are efficient, resilient, and sustainable. However, their widespread adoption is hindered by their high operating temperatures, and advanced material requirements. SOFCs generate electricity by consuming methane or other hydrocarbons on-site, where the power is needed. This makes SOFC’s well suited to backup powder applications, and other systems sensitive to outages.

Notably, the fuel-to-power conversion in SOFCs does not involve combustion. This enables an electrical efficiency of around 60%, compared with 45% for a simple-cycle gas-fired power plant. Waste heat can be salvaged in both cases, boosting efficiency. However, compared to power stations, fuel cells yield more electricity for each cubic meter of natural gas consumed.

Solid-oxide fuel cells also employ combustion-less gas oxidization, a process which doesn’t emit pollutants such as nitrogen oxides and sulfur dioxide, or other harmful aerosol particles with the exhaust gas. What’s more, German and US SOFC manufacturers have reported that carbon emissions are generally 40%-50% lower for a SOFC using natural gas compared with the national power grid.

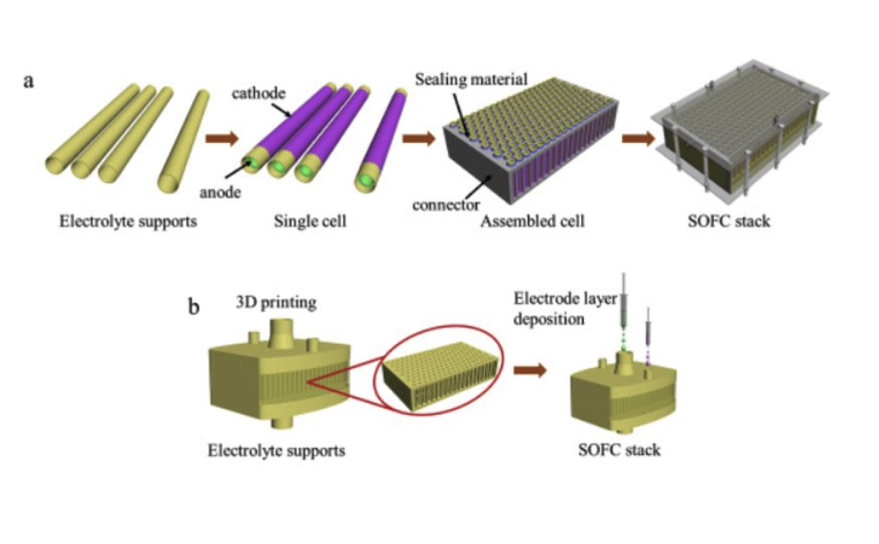

Structurally, SOFC’s incorporate a cathode, an anode, and a layer of ceramic electrolyte material between them which provides ionic conductivity. This layer is key to determining how well the electrolyte conducts oxygen ions, in turn enabling the chemical reaction that yields energy. The level of ionic conductivity is determined by the electrolyte material used, the structure of this material, and the operating temperature of the fuel cell.

3D printing ceramic SOFCs

To produce the conductive layer, the researchers combined two common ceramic electrolyte materials into a complex hierarchical lattice structure. This structure can only be produced using additive manufacturing, and is key to maximizing the SOFCs ionic conductivity.

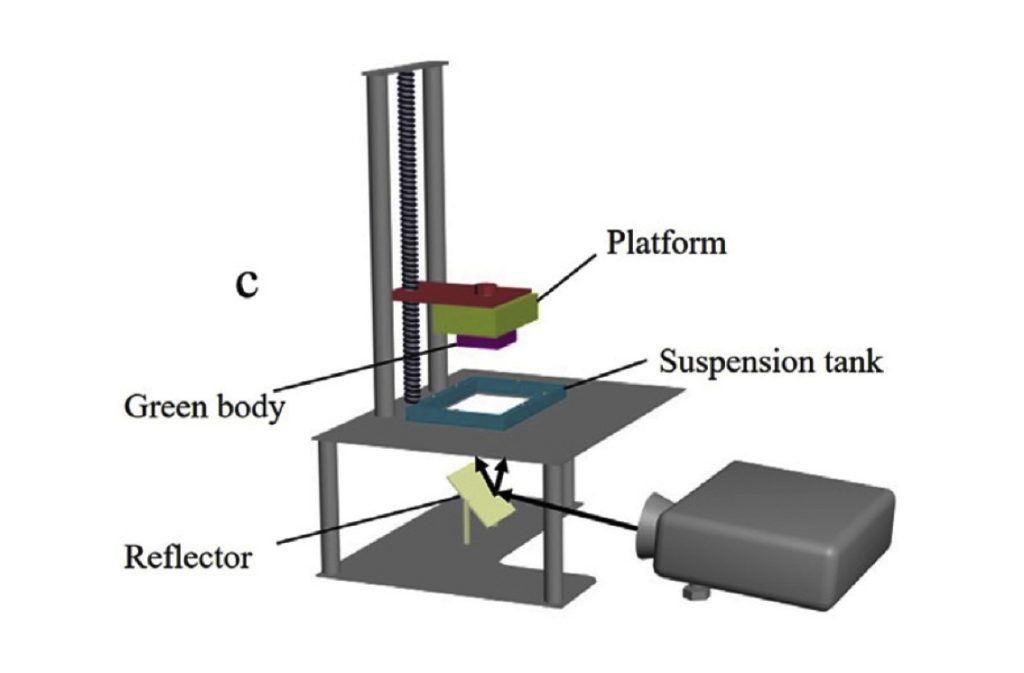

The Skoltech team used materials known as scandia-stabilized zirconia (6ScSZ) and yttria-stabilized zirconia (8YSZ) to 3D print this structure. 6ScSZ is suitable for SOFCs operating at up to 1,000℃, whilst 8YSZ can function at 750℃. Both materials were used with the team’s low-cost demonstration 3D printer, which utilizes micro-stereolithography technology and a standard video projector.

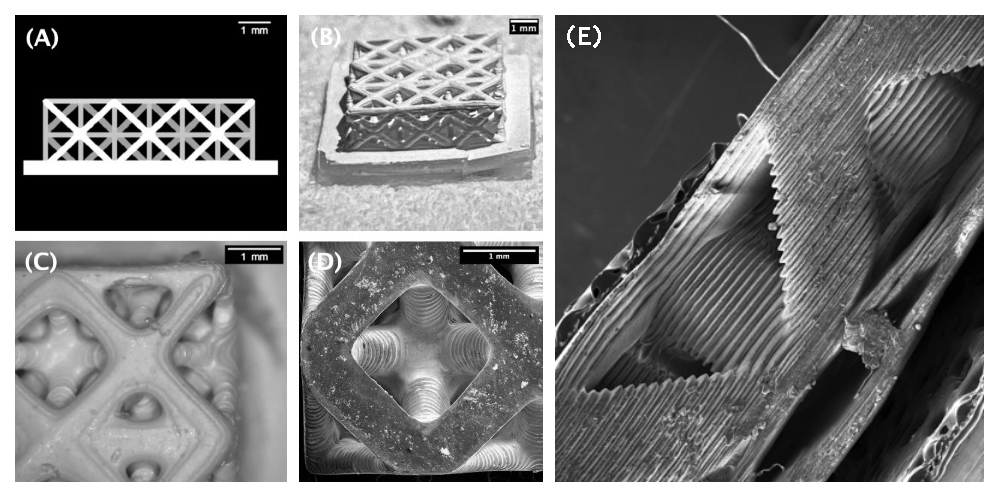

During the 3D printing process, the ceramic part is exposed to ultraviolet (UV) light to cure the polymer binder holding the material together. This results in the production of a “green part,” or semi finished product.

To fabricate a complex structure, the UV light must be delivered with a high level of precision. The research team’s demonstration 3D printer used a commercial office projector based on digital light processing (DLP) technology to achieve this. Once 3D printed, the UV-cured polymer binder is burned out of the “green part” in a furnace. Following this, the porous ceramic sample is sintered to remove residual porosity, increasing the strength of the ceramics.

In the study, Pchelintsev suggested a novel technique that combines the burning and sintering steps into a single process. The research team subsequently developed, described and carried out the 3D printing process. This included optimizing the 3D printing paste composition, post-processing the manufactured parts, and testing their electrical properties. Ultimately, the researchers successfully demonstrated the possibility of micro-3D printing highly complex ceramic structures using 6ScSZ and 8YSZ for the production of SOFCs.

Optimizing sustainable energy with 3D printing

The production of sustainable energy is certainly a growing area within additive manufacturing. The HyP3D project recently announced a breakthrough in the production of high-pressure hydrogen using ceramic 3D printing technology.

The project aims to showcase the viability of disruptive high-pressure Solid Oxide Electrolysis Cell (SOEC) technology. Funded by Horizon Europe, the HyP3D seeks to combine SOEC and advanced ceramics 3D printing to enable the efficient and sustainable production of high-pressure hydrogen.

Last year, it was announced that Cornell University, alongside start-up Dimensional Energy and Austrian Ceramic 3D printing company Lithoz, had been awarded a $50,000 grant to develop novel ceramics for 3D printing clean energy reactor parts. The researchers have since worked to develop a ceramic that can withstand the high temperatures of thermocatalytic reactors. Combining 3D printing with computer modeling, the team claimed that this material could be layered into structures, specifically shaped to improve resilience and reactor CO2 conversion rates.

Elsewhere, GE Research recently announced a partnership with binder jet 3D printer manufacturer Voxeljet to advance the development and commercialization of the Advanced Casting Cell (ACC) sand binder jet 3D printer.

Part of a $14.9 million award from the US Department of Energy, this partnership is said to play a crucial role in the transition to clean power in the US. Indeed, the ACC is optimized for the efficient production of large sand casting molds used in the wind hydro energy sectors.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a ceramic lattice 3D printed as part of Skoltech’s research. Image via Igor Pchelinstev.