Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

Powder bed fusion 3D printer manufacturer Xact Metal has announced an initiative named, “Breaking the Mold: The Xact Solution to Better Tooling.”

Through this move, Xact Metal is making its metal 3D printing technology more accessible to moldmakers, aiming for faster and cheaper parts production. This approach focuses on affordability compared to other metal 3D printing methods. Xact Metal has customers who are successfully using this technology, suggesting it can be profitable for mold and tool businesses.

Xact Metal is growing its presence in the tooling industry with over 140 machines installed globally, says the company. Its approach combines metal choices, refined printing methods, and partnerships with software and polishing businesses. This creates a full solution for moldmakers, encompassing design to final part production.

“We are excited about the new possibilities direct metal 3D printing brings to our rapid prototyping capabilities and engineering labs,” said Tyler Stark, Innovation Hub leader at Spectrum Plastics Group. “Adding stainless steel printing to our current lineup of 3D thermoplastic printers not only bridges the gap for fixtures and tooling but also speeds up significantly the prototyping process, enabling us to meet our customers’ most complex device development needs and in rapid fashion.”

Affordable metal 3D printing makes tooling accessible

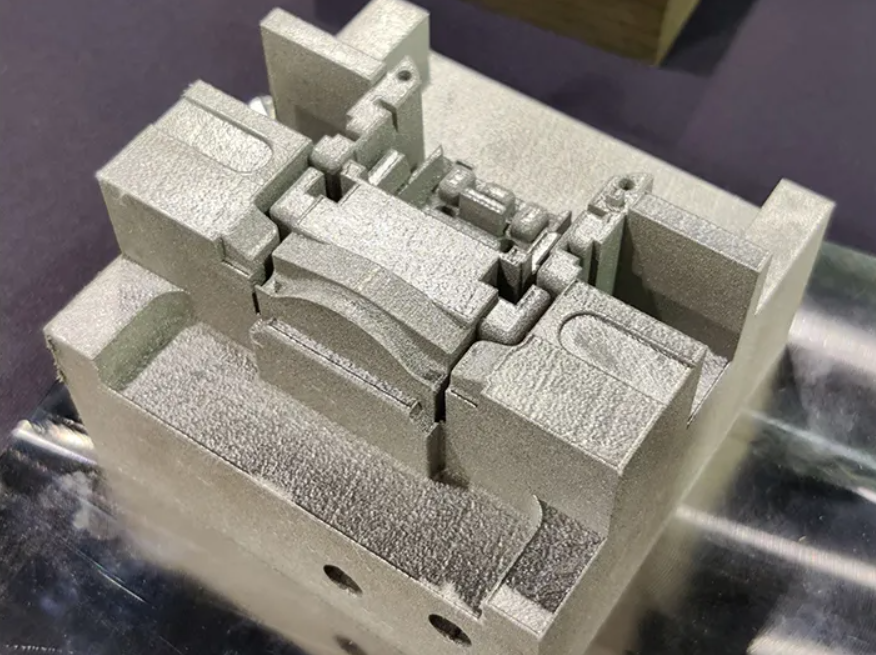

By offering economical solutions for intricate parts, Xact Metal’s 3D printers seamlessly integrate with conventional manufacturing. Its focus on affordability aims to break down cost barriers in powder-bed fusion technology. Additionally, on-site production capabilities with Xact Metal minimize downtime, allowing for a more agile production process.

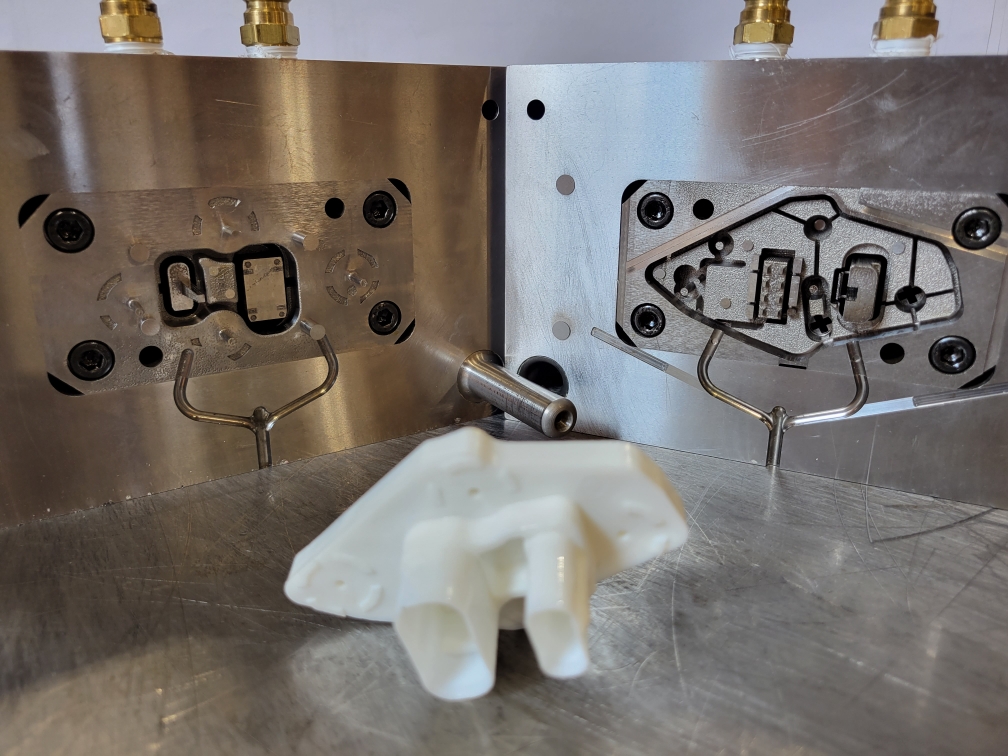

As per Xact Metal, its technology is making inroads within the tooling and molding industry. Companies across various sectors, like Actco Tool and Mfg, DuPont’s subsidiary Spectrum Plastics Group, JST, and plastics packaging company The Plastek Group, have strategically invested in Xact Metal. All these companies utilize the technology for a specific purpose: creating complex tool inserts used in injection molding processes.

“Actco has nearly six decades in close tolerance tool and die work, and we’re actively looking to the future by adding more close tolerance equipment to our toolbox,” said Dana Gruber, President of Actco. “The Xact Metal XM200G fits that bill. The 20-micron build layer and compact machine design allows us to meet our customer’s needs.”

Recently, Xact Metal collaborated with Uddeholm to provide Corrax powder for its 3D printers. Corrax is a new material with two key properties: it lacks cobalt and resists corrosion. Additionally, it can be polished to a very smooth (A1) surface finish. This collaboration allows moldmakers to create improved mold inserts and tooling components, resulting in faster production and higher quality.

Moreover, Xact Metal has broadened its offerings through collaborations with Oqton and Dlyte Polishing Solutions (GPAINNOVA). Oqton’s advanced software, including automated conformal cooling channel design, streamlines the integration of 3D printing (additive manufacturing) into the tooling and molding process. Additionally, the partnership with Dlyte Polishing Solutions provides a complete workflow solution for achieving high-quality surface finishes on additively manufactured tooling components.

Is metal AM suitable for tooling applications?

The use of metal AM is impacting the tooling industry by enabling the creation of complex tools with unique features. While cost-effective for low-volume applications, this technology offers advantages in design freedom and lead times compared to traditional methods.

Much recently, Mantle announced its expansion in the tooling sector with 3 new customers signing on to utilize its metal 3D printing technology. DuPont’s subsidiary Spectrum Plastics Group, Heyco Products, a Penn Engineering company, and General Pattern are the latest to join Mantle’s growing client base.

This expansion highlights the significant time and cost reductions Mantle’s technology offers in tooling production. Additionally, Mantle shared an example wherein Westminster Tool leveraged Mantle’s 3D printers for tooling applications. In doing so, the company was able to rapidly produce complex mold inserts, slashing traditional lead times by 50%.

French 3D printing company AddUp launched AISI 420 steel for tooling manufacturers compatible with FormUp 350 machines. This material enables complex mold creation with minimal post-processing thanks to AISI 420’s strength, corrosion resistance, and use in injection molding. Its collaboration with Aachener Werkzeubau Akademie has demonstrably produced high-durability, low-porosity molds.

On another note, binder jet 3D printing company ExOne provides a comprehensive suite of 3D printed tooling solutions under the X1 Tooling brand. Launched in 2021, X1 Tooling boasts a vast selection of industrial-grade options for various manufacturing processes, including plastic molding, forming, composite work, and metal casting.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows Xact Metal printed automotive connector insert on a tool with the corresponding plastic injection molded final part. Image via JST.