Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

Polish startup specializing in sustainable 3D printing GREENFILL3D has unveiled a series of novel solutions under its COLORISED brand.

These solutions address issues faced during stretch ceiling installation, providing contractors with effective alternatives. Initially recognized for ECO Lampshades and colorful protective frames, the COLORISED brand now offers specialized products, including solutions tailored for the stretched ceiling sector, widely adopted in European interior finishing.

Made of foil or eco-friendly fabrics, stretch ceilings provide a flexible substitute for conventional plasterboard or ceiling coffers. Their ease of installation and ability to generate visually striking lighting effects make them popular choices in both commercial and residential environments.

While working within the stretch ceiling industry, GREENFILL3D recognized a critical need for solutions to simplify contractors’ tasks. Many contractors faced challenges due to the lack of suitable products on the market, which could be attributed to either limited availability or technological constraints.

Solutions target contractor pain points

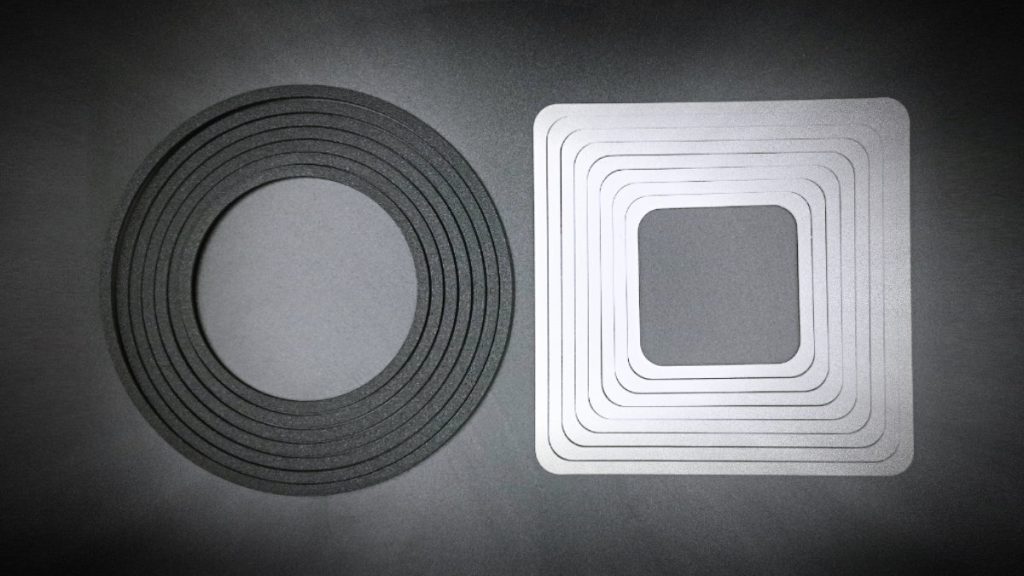

A notable innovation from GREENFILL3D is the creation of protective rings for lighting installation on stretch ceilings. Crafted from eco-friendly materials with temperature resistance and flame-retardant properties, these rings tackle a significant issue for contractors by preventing ceiling foil tearing during fixture installation. These are available in black and white and various sizes, offering customization and reliability that surpass existing products on the market.

The choice to employ 3D printing for producing these rings arises from the shortcomings of current market offerings, mainly from countries under sanctions, says the company. Conventional rings often necessitate bulk purchases, feature low-quality PVC material, lack customization options, and have limited size availability. In contrast, COLORISED protective rings offer enhanced stiffness, non-flammability, and customizable features, addressing the deficiencies of traditional options.

Moreover, GREENFILL3D has introduced a repair kit for PVC stretch ceilings, doubling as an inspection or ventilation grille. This multifunctional solution tackles common problems like ceiling damage and ventilation requirements, providing contractors with useful tools to improve their operations.

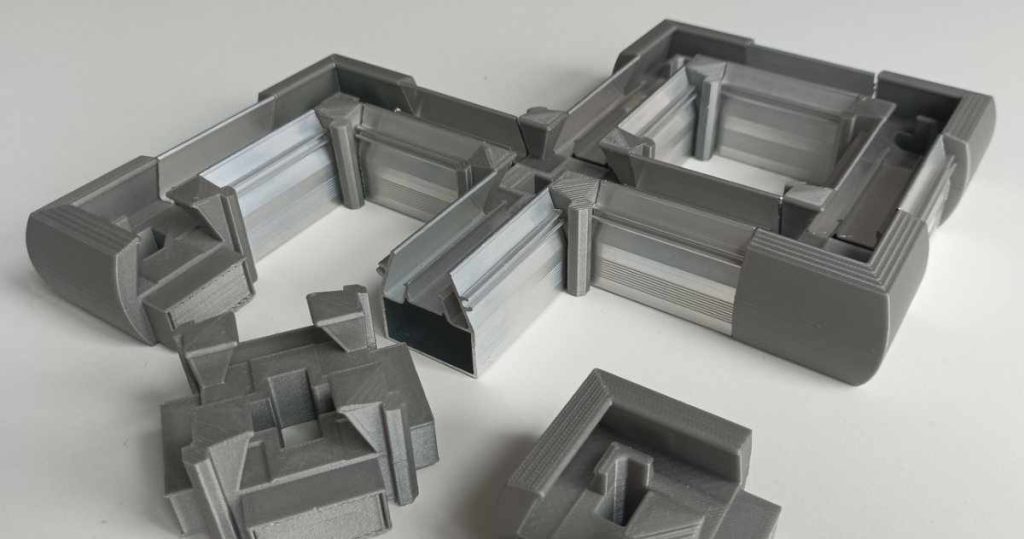

Additionally, the company has created connectors for aluminum profiles utilized in stretch ceiling installations. These connectors remove the necessity for cutting or welding, streamlining the installation process and enabling improved integration of LED strips. With more than 20 designs accessible, the COLORISED connector system accommodates various mounting profile variations, providing contractors with flexibility and user-friendliness.

Lastly, GREENFILL3D has developed the C-Roller, a tool crafted for securing wall seals in aluminum profiles while tensioning ceiling fabrics. This tool presents a cost-effective and practical substitute for existing Chinese equivalents, furnishing contractors with an efficient solution for their installation requirements.

3D printing for interior design

3D printing offers unique possibilities for customization, with designers creating one-of-a-kind furniture and personalized accessories based on individual preferences. Beyond aesthetics, 3D printing allows for the exploration of complex shapes and functionalities, potentially leading to more ergonomic furniture and sustainable design options through the use of recycled or bio-based materials.

For instance, the University of Waterloo‘s School of Architecture crafted Canada’s first 3D printed masonry wall dubbed “Hive.” Consisting of 175 unique clay blocks, it graces the 24th-floor reception of 16 York Street, Toronto, commissioned by SDI Interior Design for the Investment Management Corporation of Ontario (IMCO).

Blending traditional ceramics with computational design and additive manufacturing, the honeycomb-like structure optimizes material use and durability. Leveraging clay’s natural fluidity, the team iterated designs digitally and physically, crafting bespoke clay mixes for printing, and achieving abstract geometries for light and privacy.

A year before this, Flashforge demonstrated how its 3D printing technology enhances furniture design and production processes, broadening additive manufacturing’s scope in the industry. Collaborating with an unnamed furniture manufacturer, Flashforge reduced prototyping time from 7-10 days to 2-3 days using its Creator 4 printer.

The project showcased benefits like shortened cycle times, flexible processes, and diverse material options, suggesting widespread industry applicability. In doing so, Flashforge’s efforts showcased the potential for innovation in furniture manufacturing through advanced AM techniques.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows COLORISED protective rings. Photo via GREENFILL3D.