3D printing companies EOS, Arkema, General Lattice, and DyeMansion, have collectively developed the Digital Foam Architects network.

Featuring Digital Foam applications, this joint effort seeks to hasten the creation and additive manufacturing (AM) of consumer, medical, and industrial products. “Digital Foam applications can be designed and produced with tailored features for performance, protection and lightweighting. But Digital Foam is not a product, rather it is an approach to 3D printing foam-like products. The Digital Foam Architects network is another chapter in the maturation of this approach by coalescing the required AM expertise. We are very pleased to announce our first commitment to this network of experts,” Jon Walker, Digital Foam spokesperson for EOS.

Improving foam 3D printing with Digital Foam Architects network

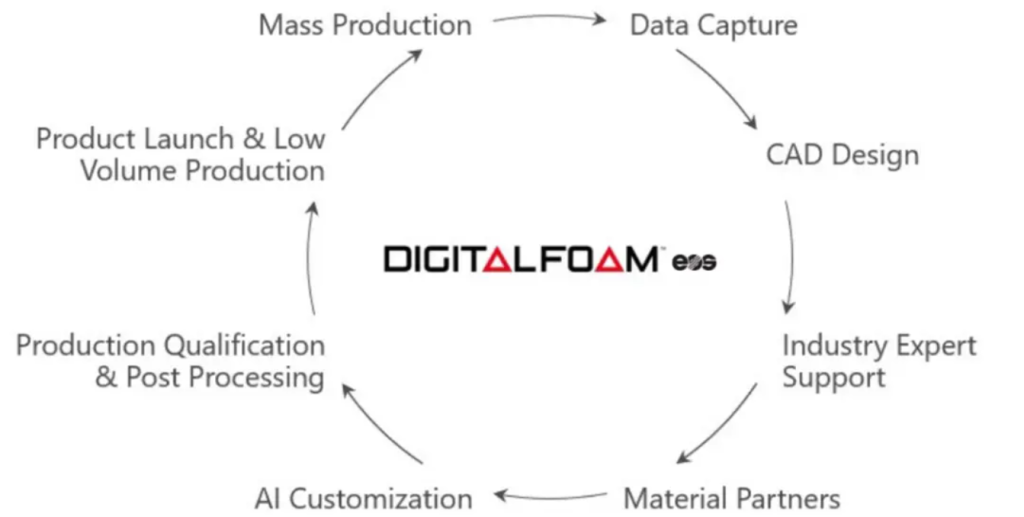

Digital Foam applications often entail complex requirements, spanning design, materials, and various aspects of AM hardware. The creation of the Digital Foam Architects network formalizes a partnership of AM experts poised to “turn creative concepts into reality.” It covers various aspects, including design software, materials, and the full spectrum of AM hardware components, such as 3D printing, post-processing, and colorization.

Central to Digital Foam is EOS’s patent, focusing on generatively 3D printed objects characterized by a flexible grid-like structure or matrix, incorporating open cells with diverse attributes. This patent contains a broad spectrum of 3D printed lattice structures, presenting a multitude of opportunities for AM innovation. As Digital Foam continues to be employed as a flexible lattice solution in additive manufacturing, the network anticipates expanding its array of partners, says EOS.

“Arkema is committed to supporting new additive manufacturing application development through more sustainable material solutions. In collaboration with EOS, we continue to push the boundaries on what is feasible in 3D printing by combining strong enablers, such as Digital Foam, and new materials, such as Pebax® elastomers. We look forward to the growth of Digital Foam and we will continue to play an active role in this program,” Adrien Lapeyre, Director of Arkema 3D printing program.

How foam technology has been used over the years

US-based sports technology and ice hockey equipment brand Bauer Hockey collaborated with EOS to create personalized 3D printed hockey helmets. These helmets, offered through Bauer’s MyBauer custom equipment program, aim to enhance ice hockey gear for the mass market using EOS’s patented 3D printed Digital Foam technology. This process involves scanning the player’s head to create a digital file and then utilizing Selective Laser Sintering (SLS) to produce a custom helmet insert. Bauer sought to achieve “mass customization,” according to Mathieu Dejardins, Senior Brand Manager of Protective Equipment at Bauer.

In 2019, EOS North America and its applied engineering consultancy Additive Minds launched the Digital Foam program. This hub simplifies the process of bringing 3D printed foam products to market. It supports customers in CAD, materials, part qualification, and 3D printing, with engineering software from nTop for design, analysis, and preparation of foam material. Customers can fast-track the production of foam 3D printed products, such as protective headgear, orthotics, and performance footwear.

Who will win the 2023 3D Printing Industry Awards? Make your nominations now!

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Digital Foam Architects Network Process Graphic. Photo via EOS.