US 3D printer manufacturer 3D Systems has announced VSP Connect, a centralized, cloud-based surgical planning portal that incorporates automated workflows and artificial intelligence (AI).

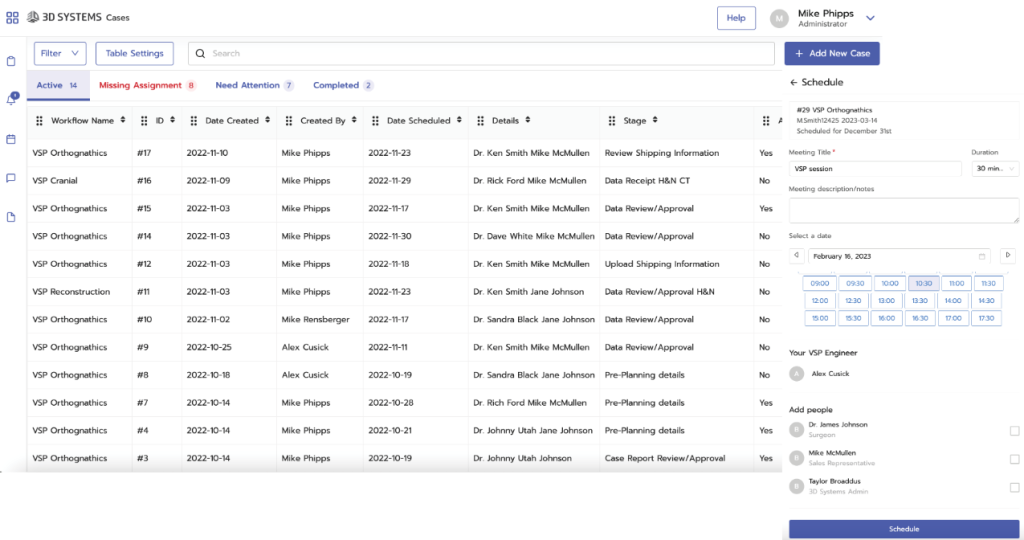

VSP Connect, the company’s newest addition to its VSP surgical planning solutions, provides device makers and surgeons with real-time patient case visualization and enhanced collaboration functionalities. VSP Connect is driven by Enhatch, with whom the company announced a partnership to scale personalized medical device delivery in 2022. Enhatch’s AI and automation systems are combined with 3D Systems’ FDA-cleared workflows for patient-specific systems, which include sophisticated software, expert planning services, personalized implant and instrument design, and leading 3D printers and manufacturing techniques. This combination provides transparency for healthcare systems and medical device manufacturers while also streamlining the presurgical planning process, allowing personalized procedures to be more effective while delivering better results.

“VSP Connect is the missing link in surgical planning, bridging the gap between patient care and cutting-edge technology,” said Michael Phipps, CTO/president, of Enhatch. “With Enhatch’s advanced AI and automation capabilities, the portal gives surgeons the opportunity to reduce planning times and perform more patient-specific surgeries.”

Functionalities of VSP Connect

To offer thorough patient-specific solutions, 3D Systems’ VSP surgical planning solution integrates “best-in-class” digital workflows with the industry’s broadest additive manufacturing portfolio of printers and materials. VSP Connect improves these functionalities by implementing automated workflows that enhance communication among all stakeholders (e.g., device representatives, case managers, patient-specific device designers, and surgeons) while enabling adherence to industry regulations and internal accuracy protocols. VSP Connect uses AI to provide pre-populated designs that are customized to both individual surgeon preferences and standard product types.

The reliable, cloud-based portal combines disparate processes into a single, user-friendly interface that allows for 24-hour access to case status and the capacity for sending notes or alerts. This streamlined presurgical planning process, from surgical planning to the production and distribution of patient-specific implants and instruments, results in shorter procedure times and better patient outcomes.

For over a decade, 3D Systems has collaborated with surgeons to arrange over 150,000 patient-specific cases and produce more than two million implants and tools for 100+ CE-marked and FDA-cleared devices from its “world-class”, FDA-registered, ISO 13485-certified premises in Littleton, Colorado, and Leuven, Belgium. The company will display its solutions, including VSP Connect, in its booth (#3256) at the AAOS 2023 Annual Meeting, March 8-10 at the Venetian Convention & Expo Center in Las Vegas, Nevada.

“3D Systems is on a mission to transform healthcare through the use of additive manufacturing to make patient care easier and smarter,” said Benjamin Johnson, vice president, of portfolio and regulatory, healthcare, at 3D Systems. “With VSP Connect, we are providing access to the healthcare industry’s most complete additive manufacturing ecosystem. Combined with Enhatch technology, our unified approach makes it easier to deliver patient-specific implants and instrumentation in a more efficient, cost-effective manner. It’s part of our ongoing commitment to innovation and helps ensure our customers are at the forefront of medical device development and healthcare delivery.”

Additive manufacturing being a source of advanced surgical planning

Previously, Materialise, a developer of additive manufacturing software, released Mimics Planner to help streamline thoracic surgery. According to the company, this platform uses improved 3D modeling to help prepare for segmentectomy and lobectomy surgeries in a matter of minutes. Mimics AI-enabled CT heart tool for heart chamber segmentation, according to the whitepaper. Materialise claims tasks like manually segmenting heart chambers are time-consuming, laborious, and error-prone. Implementing this method introduces many efficiencies to an engineer’s workflow by saving time while improving accuracy.

Furthermore, Californian Rady Children’s Hospital released the novel Digital Imaging and Communications in Medicine (DICOM) standardization software. ‘Media2DICOM,’ developed in-house by the hospital’s Helen and Will Webster Foundation 3D Innovations (3DI) Lab, transforms 3D models of patients into DICOM files, which are commonly utilized by physicians to share data. As a result, the program enables medical personnel to more easily obtain anatomical 3D reconstructions, improving efficiency while assisting them in tailoring therapies to enhance clinical outcomes in children.

What does the future of 3D printing for the next ten years hold?

What engineering challenges will need to be tackled in the additive manufacturing sector in the coming decade?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

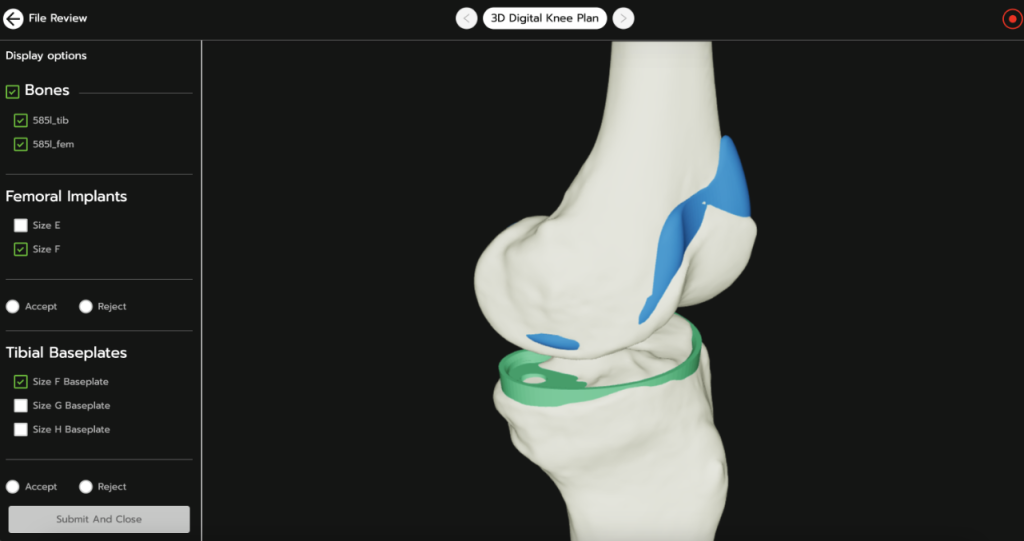

Featured image shows 3D digital knee planning. Image via 3D Systems.