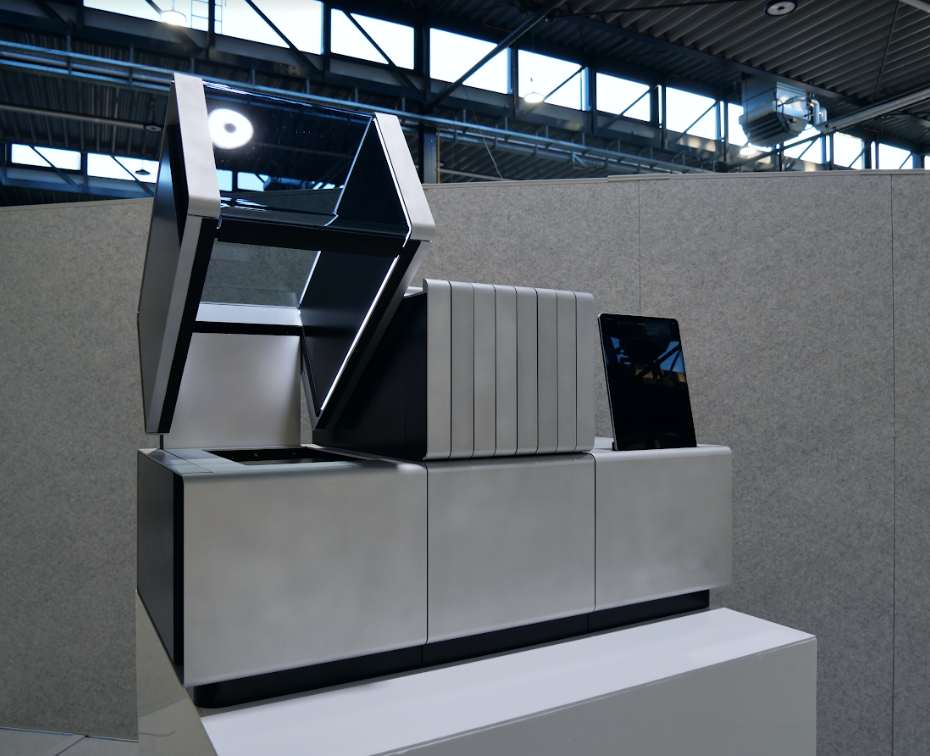

Berlin-based 3D printing start-up Quantica has introduced a new Desktop system named NovoJet C-7 at Formnext 2022.

The NovoJet C-7 is an open printing platform that uses Quantica’s ultra-high viscosity jetting technology to develop 2D and 3D applications. It was designed for research institutes, R&D labs, and organizations interested in developing new additive manufacturing materials and workflows. The printer can be employed for customized and low-volume production in addition to feasibility testing and application development, allowing for a seamless transition from lab to production.

“This new system unlocks enormous possibilities for the material deposition industries, giving material developers the ability to move past the limitations of low-performance fluids and start developing new formulations with better properties of interest. In the end, we empower organizations to build products in new and exciting ways,” said Ramon Borrell, CTO of Quantica.

Characteristics of the NovoJet C-7 desktop system

The first characteristic, Material Experimentation, employs printheads capable of handling a broad range of liquids with viscosities surpassing 380mPa•s at jetting temperature, equating to approximately 4000mPa•s at ambient temperature. It is suitable for use in conjunction with experiments with liquids containing a high particle loading.

The next feature offered by this desktop system is new material combinations. The system can control up to 7 material channels, allowing users to choose new material combinations with improved mechanical properties, color fidelity, and aesthetics. System Customization provides customizable integrations for R&D requirements.

The ability of NovoJet printhead technology to print materials that are 15 times more viscous than legacy inkjet printheads, according to Quantica, is the power of NovoJet printhead technology. This opens up new opportunities for producing high-value end-part products with characteristics like toughness, temperature resistance, conductivity, biocompatibility, and flexibility in a single cycle. Several industry partners, primarily from the dental, medical, and electronics sectors, have begun working with Quantica to create targeted solutions based on novel functionalities, says the company.

“Quantica is already exploring several applications in the dental, healthcare, consumer goods, and electronics industries. We are excited to support these, and the many other, industries in breaking down current inkjet barriers and limitations,” added the CTO of Quantica.

Multi-material 3D printing

Previously, Brinter, a Finnish bioprinting company, developed what it describes as the world’s first multi-material, multi-fluidic bioprinting printhead. The digital multifluid printing tool head, which was designed for use with the company’s own 3D bioprinters, had undergone pilot testing with a handful of customers. The device is directed at research institutions and pharmaceutical companies, and it hopes to enable higher-precision tissue engineering and regenerative medicine applications such as tissue damage repair, biological function replacements, and localized disease treatments.

Furthermore, since its release in 2020, Lithoz, the leading industrial ceramic 3D printer developer, took a step toward the future of multi-material 3D printing with its CeraFab Multi 2M30 system. The machine, which uses the company’s Lithography-based Ceramic Manufacturing (LCM) technology, is distinguished by its capability to print with two materials at the same time. This comprises ceramic-metal, ceramic-polymer, and ceramic-ceramic combinations.

Elsewhere, Massachusetts-based 3D printer manufacturer Desktop Metal (DM), announced the acquisition of Belgian recoater system developer Aerosint. Aerosint’s patented Selective Powder Deposition technology allows it to 3D print multiple materials at the same time, increasing powder efficiency, cost, and part throughput. Aerosint iteratively developed a powder re-recoating system capable of selectively depositing two or more powders into multi-material layers, since its inception in 2016. The company’s technology, which is compatible with polymers, metals, and ceramics, allows complete three-dimensional control of placement during printing and can be incorporated into any LPBF, SLS, HSS, or binder jetting setup.

Follow this link for all the Formnext 2022 news.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Feature image shows NovoJet C-7 Desktop system. Image via Quantica.