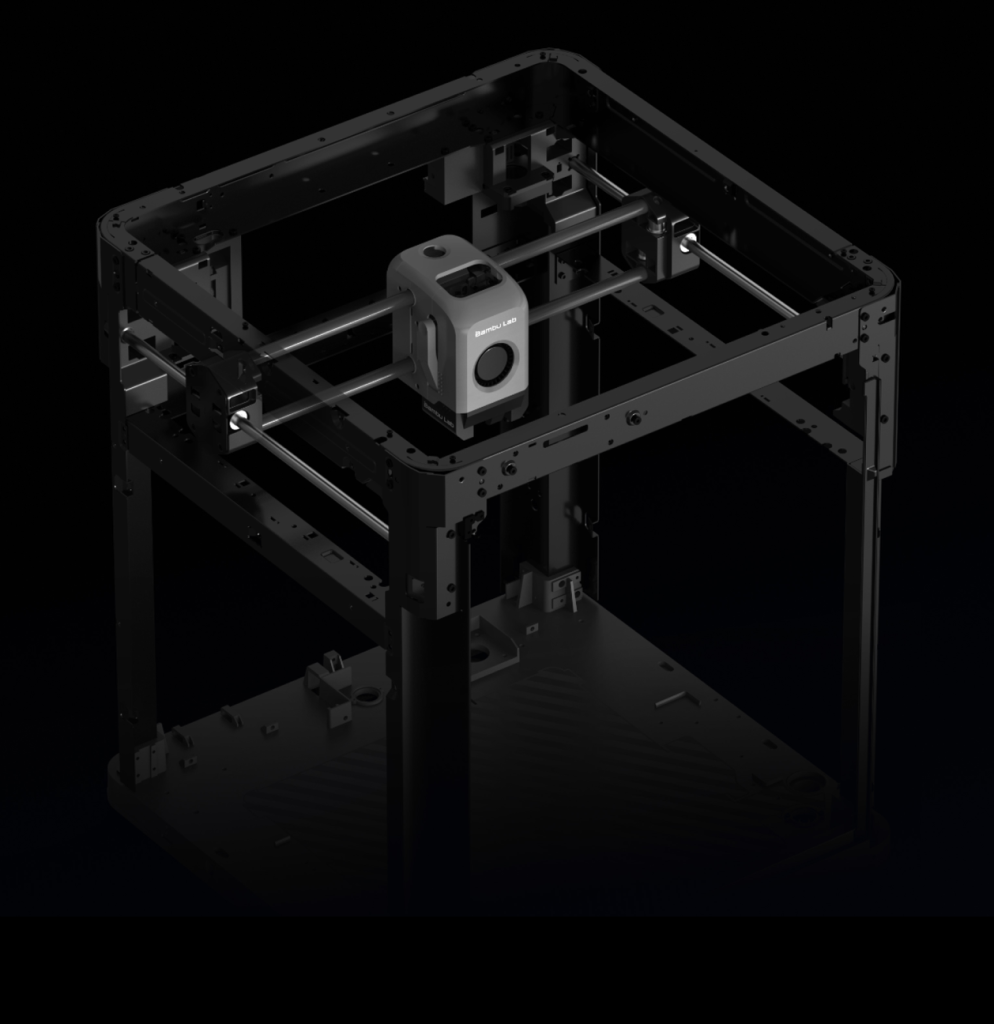

Shenzhen-based 3D printer manufacturer Bambu Lab has announced in a blog post that it will allow users to install third-party firmware on its X1 FDM 3D printer through an optional firmware update.

Accessing this update will require users to sign a waiver. Described as a ‘one way ticket,’ this agreement revokes the warranty of the 3D printer. Users who sign up will lose access to Bambu Labs support services, and take sole responsibility for their X1’s security and safety.

This decision follows a project by third party firmware developer X1Plus, to jailbreak the X1 3D printer and run external firmware. X1Plus’s firmware has been developed by a community of users who wish to add new features to their X1 3D printers. These features include automatic bed leveling and input shaping calibration graphs.

Bambu Lab initially patched the loophole that enabled XPlus to function, blocking the ability to run third party firmware or root the X1. However, the company has now compromised on this stance, following a meeting with X1Plus’s leading developer.

According to Bambu, this new opt-in firmware will likely be available in two to three weeks, with the company still needing to set up the confirmation page and complete legal consultations.

Bambu Lab’s closed-source approach

Bambu Lab has taken a closed-source approach to its 3D printers, calling this the ‘Apple approach,’ as opposed to a more open-source ‘Raspberry Pi model.’

This approach sees Bambu Lab 3D printers incorporate closed and proprietary hardware, with the company’s products intended to be the finished article. As such, the hardware and firmware of Bambu 3D printers have been designed with a view to controlling all aspects of their development. However, whilst Bambu does offer its own proprietary filaments, the company’s 3D printers are compatible with third-party materials.

“Is the Apple way the right approach? It’s too early to tell, but it’s the path we’ve chosen, and we intend to stay on it,” commented Bambu.

Whilst acknowledging that this approach may be disappointing to ‘DIY-spirited’ users, the company argues that a closed-source system offers a number of benefits. For instance, universal control over hardware and software is said to ensure high quality standards which serve as a baseline for the product. Future updates can then build on this baseline, ensuring consistent improvements in the future through regular updates, patches and bug fixes. This reportedly makes the troubleshooting process quicker and easier, improving the customer support experience.

What’s more, Bambu argues that opening its 3D printers up to root access would allow users to make changes they don’t fully understand. Rooting is the act of jailbreaking a device, granting additional freedom and administrative control over the 3D printer. According to Bambu, this could cause problems that are hard to replicate and solve.

‘While we fully recognize that a small percentage of users are enthusiasts that know what they are doing, there will always be a significantly higher percentage of users that will not, leading to bad 3D printing experiences and inaccurate feedback shared online,’ the company argues.

A ‘one-way ticket’ to third-party firmware

Bambu has stated that it is now giving users the choice to install third-party firmware and root the system ‘at their own risk.’ In addition to waiving official support resources and taking sole responsibility for the X1, Bambu has warned users that it cannot guarantee or block the use of the cloud services for those using third party firmware.

To gain access to the new open-source capabilities, users must sign the waiver of warranty and safety responsibility via a dedicated web page. Once signed, users will be able to download a new firmware which enables rooting and third-party firmware to be installed.

Following this, new Bambu Lab firmware updates will include security measures designed to prevent rooting on non-waivered 3D printers. Moreover, Bambu has stated that it can’t guarantee the ability for users with third-party firmware to revert back to the official firmware. However, the company has promised to “cooperate with the X1Plus team as much as possible” to allow this. Warranty and support will not be reinstated after switching back to the OEM’s firmware, with the waiver acting as a ‘one-way ticket.’

Bambu has also stated that it has undertaken a thorough review of its log system, and has acknowledged the need for improvements. The company has noted that its log file contains extensive information. While extensive logging may be necessary during the development phase, ‘it’s not necessary on customer printers.’

Therefore, Bambu has confirmed that the new open-source-enabled firmware will refine the log system and remove all debug logs not necessary for end-users.

‘This does not imply that previously submitted logs infringed upon your privacy,’ the company added. ‘The log file is encrypted, and access to the decrypted logs is strictly controlled – not even our first line support agents have direct access to its contents, getting diagnosis data instead of the raw log content from the system. Furthermore, 14 days after a support ticket is closed, all related log files are deleted from our server.’

Open source 3D printing

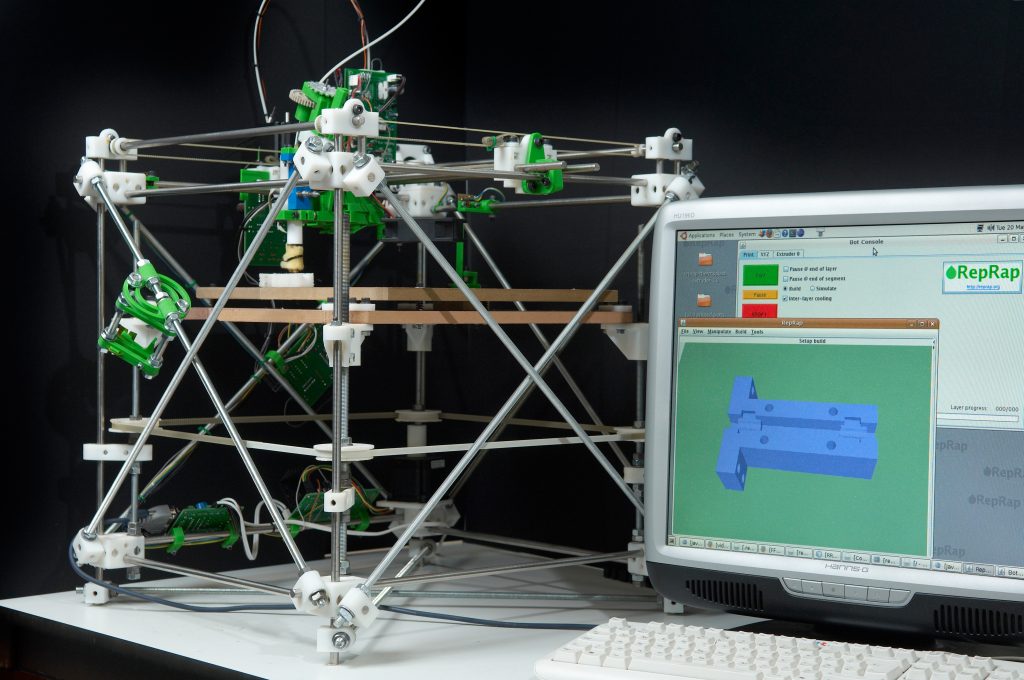

Open source was central to the philosophy of many desktop 3D printing pioneers. The 3D printing community that collalessed around Dr. Adrian Bowyer’s RepRap project held the open source nature of projects, and acknowledgment of the work done by community members as sacrosanct.

Violations of this were met with a severe reaction, as the community response to Bre Pettis taking MakerBot closed source illustrates. It is a firm belief within the RepRap and wider desktop 3D printing community that the free collaboration and development enabled by open source has been key to the growth of desktop 3D printing technology. The RepRap community also views open source as being key to democratizing 3D printing, making FDM technology accessible to anyone.

Those initial companies that grew from the RepRap project include Prusa Research, Aleph Objects with its open-source LulzBot 3D printer, UltiMaker, and MakerBot. 3D printing software platforms such as Marlin Firmware, Slic3r, and Cura were also born out of the RepRap project, being conceived with an open-source philosophy.

The fate of these RepRap pioneers has been mixed. Aleph Objects was acquired by Fargo Additive Manufacturing Equipment (FAME 3D) in 2019, while MakerBot has since merged with UltiMaker. UltiMaker drew criticism in 2017 when it announced that it would file its first patent to protect the Active Bed Leveling technology found inside the UltiMaker 3 series.

At the time, Aleph Objects’ Director of Marketing, Ben Malouf, stated that this move could have a “chilling effect” on 3D printer innovation. Josef Prusa argued that “patents just consume time and make product development slower.”

Prusa, now a leading manufacturer of desktop 3D printers, remains a key proponent of open-source 3D printing, believing it to be key to further advancing desktop 3D printing technology. The company has asserted that its products will always be open source, and will never be patented. Indeed, Prusa has stated that its recent success was only possible “thanks to the great 3D printing community and open-source philosophy.”

In May 2023, fellow Shenzhen-based 3D printer manufacturer Creality announced the release of the open-source code for its Ender desktop 3D printer series.

Through this open-source code, users can customize their Ender 3D printers to optimize performance and stability. At the time, Creality also announced that its Ender-3 3D printer had become the first Chinese 3D printer to receive certification from the Open Source Hardware Association. “Open-source platforms foster collaboration and knowledge sharing among users, developers, and enthusiasts, driving the advancement and popularization of 3D printing technology,” the company stated in a press release.

Elsewhere, Barcelona desktop 3D printer manufacturer BCN3D has released the original design files for its Sigma and Sigmax R19 3D printers. Having been founded on an open source 3D printing philosophy, these files allow others to benefit from developments in the R19 project. This move formed part of a BCN3D initiative to release all the files for both the software and hardware of its 3D printers.

In response to this announcement, RepRap pioneer Richard Horne, better known as RichRap, stated that BCN3D’s decision was a “step beyond” the usual release of 3D printer CAD files.

“This release of the Sigma R19 and the Sigmax R19 source files also comes [with] an even greater gift to the open source hardware community, this being the inclusion of the designs and information that BCN3D use to manufacture, test and assemble all aspects of the machine during production,” commented Horne.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

The Bambu Lab X1-Carbon 3D printer. Image via Bambu Lab.