Researchers from the Massachusetts Institute of Technology (MIT) have successfully 3D printed soft, magnetic-cored solenoids that are more powerful than those made with alternative methods.

These electromagnets incorporate a coil of wire wrapped around a magnetic core and play a key role in many electronic devices such as dialysis machines and respirators.

Having modified a commercially available multi-material 3D printer, the researchers were able to fabricate the solenoids in a single step. It is hoped that this approach will increase the accessibility of key electronic devices for people with limited resources, or those living in remote areas.

“There is no reason to make capable hardware in only a few centers of manufacturing when the need is global. Instead of trying to ship hardware all over the world, can we empower people in distant places to make it themselves?” stated Luis Fernando Velásquez-García, senior author of the MIT study which was recently published in the journal Virtual and Physical Prototyping.

“Additive manufacturing can play a tremendous role in terms of democratizing these technologies.”

These 3D printing capabilities could also play a key role in manufacturing electronic devices during future space missions. Rather than sending replacement components from Earth, similar 3D printers could be used to fabricate the parts where they are needed, saving time and money.

Producing solenoids with multi-material 3D printing

Additive manufacturing can be used to produce solenoids of almost any shape or size. However, producing these devices requires the precise combination of multiple materials.

To produce their solenoids, the MIT team utilized a dielectric material which serves as an insulator, a conductive material that forms the electrical coil, and two soft magnetic materials for the core – one based on a biodegradable thermoplastic and the other on nylon.

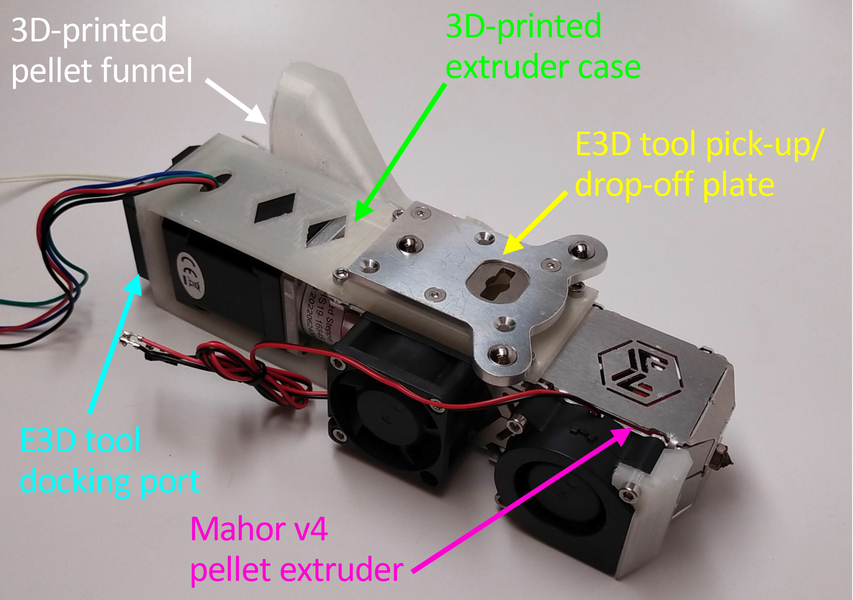

Combining these materials poses challenges for conventional, single-nozzle 3D printers which can only extrude a single material at a time. Therefore, the MIT researchers leveraged a 3D printer with four extruders, each dedicated to a different material.

One of the nozzles was modified to extrude pellets rather than filaments. This enabled the team to incorporate a soft magnetic nylon 12 material studded with metallic micro-particles, which was not available in filament form. Extra ventilation was also added to help cool the conductive material, preventing the nozzle from clogging during extrusion.

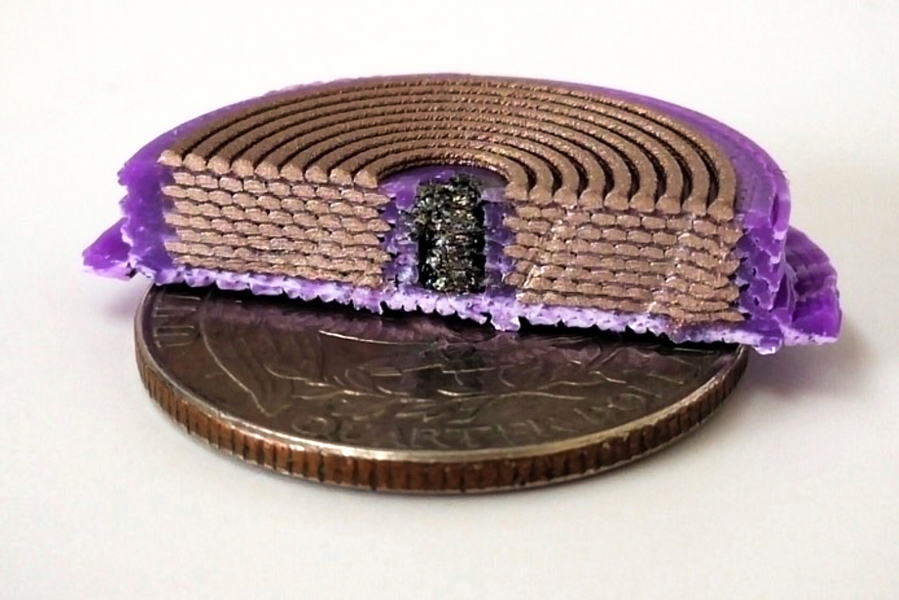

Costing around $4,000, the team’s modified 3D printer can produce complete solenoids consisting of eight layers, with coils and insulating material precisely placed around the magnetic core. Thanks to the precision offered by this approach, the team successfully produced devices 33% smaller than those made with alternative 3D printing methods.

Incorporating more coils within a smaller area can boost amplification. Therefore, MIT’s solenoids are capable of withstanding twice as much electric current and generating a magnetic field three times stronger than those made with other 3D printers.

By fabricating each device as a single piece, the researchers also eliminated the potential for defects that could be introduced during post-processing and assembly. This can also reduce production costs and cut manufacturing waste.

Looking to the future, the researchers will next work to enhance the performance of their 3D printed solenoids, which could include using materials with better properties. Additional modifications that could more precisely control deposition temperature are also being considered, with the hope of reducing defects.

Advancements in 3D printed electronics

The use of additive manufacturing growing technology in the production of electronic devices. Back in 2022, researchers from the Tallinn University of Technology and the Estonian University of Life Sciences investigated the use of 3D printing for the production of soft magnetic cores used in electrical devices.

The research team’s comprehensive laser-based metal 3D printing workflow can reportedly produce soft magnetic composites with superior magnetic properties. The researchers argued that this approach overcomes key challenges associated with preserving core efficiency. As such, the approach offers value for various electrical systems such as electromagnets, transformers, electric motors, generators, inductors, and other magnetic assemblies.

Elsewhere, Scientists from Nanyang Technological University Singapore (NTU Singapore) and the Singapore Centre for 3D Printing (SC3DP) have developed a multi-material 3D printer for the production of wearable electronics.

Produced in collaboration with Japanese electronics firm Panasonic, the 3D printer incorporates multi-wavelength, high-powered lasers that can convert common carbon-based materials into a new type of highly porous graphene. This system seeks to meet increased market demand for flexible and wearable electronic devices that can be bent, twisted, and conformed to various surfaces.

The partners, who have been working on this project since 2016, believe that this 3D printer could revolutionize additive manufacturing, opening new possibilities for the production of devices with unmatched functionality and flexibility.

What does the future of 3D printing hold?

What near-term 3D printing trends have been highlighted by industry experts?

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a 3D printed, multi-material solenoid. Photo via the Massachusetts Institute of Technology.