Electronics 3D printer manufacturer Nano Dimension recently announced that it has sold a DragonFly IV system to the University of Stuttgart. The University will use this advanced manufactured electronics (AME) 3D printer to develop scalable quantum sensors.

According to Nano Dimension, the 3D-electronic-integration capabilities of the Dragonfly IV will enable new possibilities for the microelectronic and photonic integration of scalable quantum devices.

“We are excited to bring the DragonFly IV with its worldwide unique capabilities into our research,” commented Professor Jens Anders, Institute Director of the Institute of Smart Sensors (ISS) at the University of Stuttgart. “The integration of qubits for quantum sensing and quantum computing is high-demanding in nature, requiring innovative, high-precision solutions; therefore, it is not often that we find technology that meets our challenging needs.”

“Engaging with Nano Dimension will help us design and manufacture the next generation of scalable quantum devices, which will revolutionize our society with applications ranging from smart prostheses and smart breath sensors over pharmaceutical research to autonomous driving,” added Anders.

Developing scalable quantum sensors

Quantum sensors employ properties of quantum mechanics to achieve high sensitivity and produce incredibly accurate measurements. These sensors are particularly useful in medicine, autonomous navigation, and renewable energy applications. Whilst promising quantum sensor prototypes have been tested, the technology still lacks the scalability and mass-manufacturability needed to enter the market on an industrial scale.

The DragonFly IV 3D printer will go to the University of Stuttgart’s ISS and 3rd Institute of Physics (PI3). These two groups are jointly working on the design and integration of next-generation quantum devices as part of Cluster4Future QSens (“QSens”), a German Federal Ministry of Education and Research (BMBF) sponsored program. QSens is dedicated to developing the next generation of scalable quantum sensors.

To achieve this, the ISS and PI3 are collaborating with 19 industrial partners and three research institutes. The project is targeting a large-scale market entry within the next three to five years.

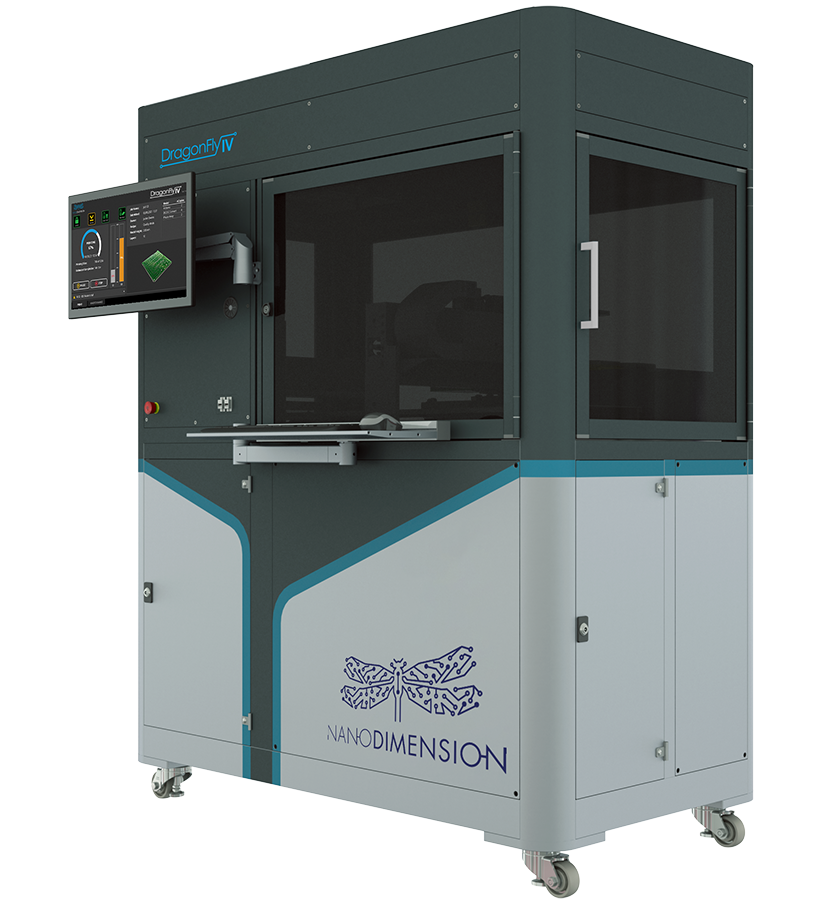

The DragonFly IV system

The DragonFly IV system plays a critical role in specialty applications for High-Performance-Electronic-Devices (Hi-PEDs). This is because the DragonFly IV can simultaneously deposit proprietary conductive and dielectric substances. In-situ capacitors, antennas, coils, transformers, and electromechanical components can also be integrated using the Dragonfly IV.

Hi-PEDs are used in a range of applications, including autonomous intelligent drones, cars, satellites, smartphones, and in vivo medical devices. What’s more, Hi-PEDs also enable iterative development, IP safety, fast time-to-market, and device performance gains.

The DragonFly IV’s 3D printing process is supported by its ‘FLIGHT’ software. This software incorporates intelligent verification, slicing, and job control functionalities that enable 3D modelling of highly sophisticated parts. The AME 3D printer is also guided by deep learning algorithms from DeepCube, improving yields and allowing for real-time 3D print correction.

Nano Dimension Chairman and CEO Yoav Stern stated that “We look forward to supporting the University of Stuttgart and their Center of Applied Quantum Technology in their ever-critical work on quantum technology. Furthermore, we are pleased that another customer has come to appreciate the value of AME to drive innovation.”

“This is particularly empowering when the work at-hand is the scalable integration of qubits for quantum sensing and computing. This field is a perfect use case for our AME system, DragonFly IV, which can be used to make specialty electronic devices with the design freedom and shorter innovation cycles of additive manufacturing,” added Stern.

3D printing and quantum research

This is not the first time 3D printing technology has been used for quantum research. Back in 2019, German nano-scale 3D printing specialist Nanoscribe joined MiLiQuant, a quantum research program.

Funded by the BMBF, MiLiQuant was a three-year project for the development of diode laser-based light sources. It was hoped that this technology would be used to further develop quantum sensors and quantum imaging devices. Much like the QSens project, the primary purpose of MiLiQuant was to initialize quantum technology at the industry level.

Elsewhere, in 2020 a team of researchers from the Korea Electrotechnology Research Institute utilized 3D printing to develop high-density quantum dot pixel arrays at the nanoscale. By embedding and solidifying liquid inks in polymer nanowires, the researchers successfully fabricated vertically freestanding pillars capable of emitting light. Characterized by their long length and high brightness, these 3D printed structures can be used to “achieve super-high-resolution display devices”.

Subscribe to the 3D Printing Industry newsletter to ensure you keep up with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a Nano Dimension DragonFly IV 3D printer. Photo via Nano Dimension.