Electronics 3D printer manufacturer Nano Dimension has announced the sale of one of its systems to a European defense customer.

For national security reasons, Nano Dimension hasn’t revealed the nation whose military has adopted its technology, but they’re understood to be the tenth western defense agency to do so. Having sold another of its DragonFly IV 3D printers, CEO Yoav Stern says the firm is now beginning to lay the groundwork for commercial applications further down the line.

“After many years of experience with advanced technologies in the Air Force, I know that leading edge products which are adopted initially by defense forces, traditionally end up creating very large size commercial markets as well,” said Stern. ”There are perhaps no greater requirements for innovation than what defense agencies command, and we are proud to be chosen as the supplier of such unique solutions.”

“Engaging this new customer is exciting for us. It proves, yet again, how irreplaceable and essential our 3D printing technologies and materials are.”

Expanding beyond electronics 3D printing

Nano Dimension has positioned itself as an early leader in the emerging electronics 3D printing sector. The company has successfully done so through the marketing of proprietary machines, which are capable of simultaneously depositing conductive silver nanoparticles and dielectric polymer inks, to form PCBs and circuits.

In 2014, Nano Dimension’s reverse merger saw it go public on the Tel Aviv Stock Exchange, in a move that foreshadowed the 3D printing SPAC merger trend seen over the last two years. Since becoming publicly-listed, the firm has managed to raise a substantial amount of capital via share offerings to finance its expansion ambitions, and at last count, Nano Dimension had $1.25 billion in funding.

To date, the 3D printer manufacturer has acquired several businesses that border its own, but not all overlap in an immediately obvious way. Nano Dimension acquired DeepCube for $70 million, a specialist in deep learning algorithms, in April 2021, before buying microprinting firm Nanofabrica, in a deal that could be worth up to $59.4 million.

This year, the firm has continued its expansion, purchasing Global Inkjet Systems for an initial $18.1 million. Nano Dimension also bought into Stratasys, acquiring 12.12% of the industry stalwart in July 2022. Given the company’s huge cash reserves, the move prompted fears of a hostile takeover, and Stratasys filed for a poison pill shortly afterwards, to prevent any such acquisition from taking place.

Nano Dimension’s DragonFly system

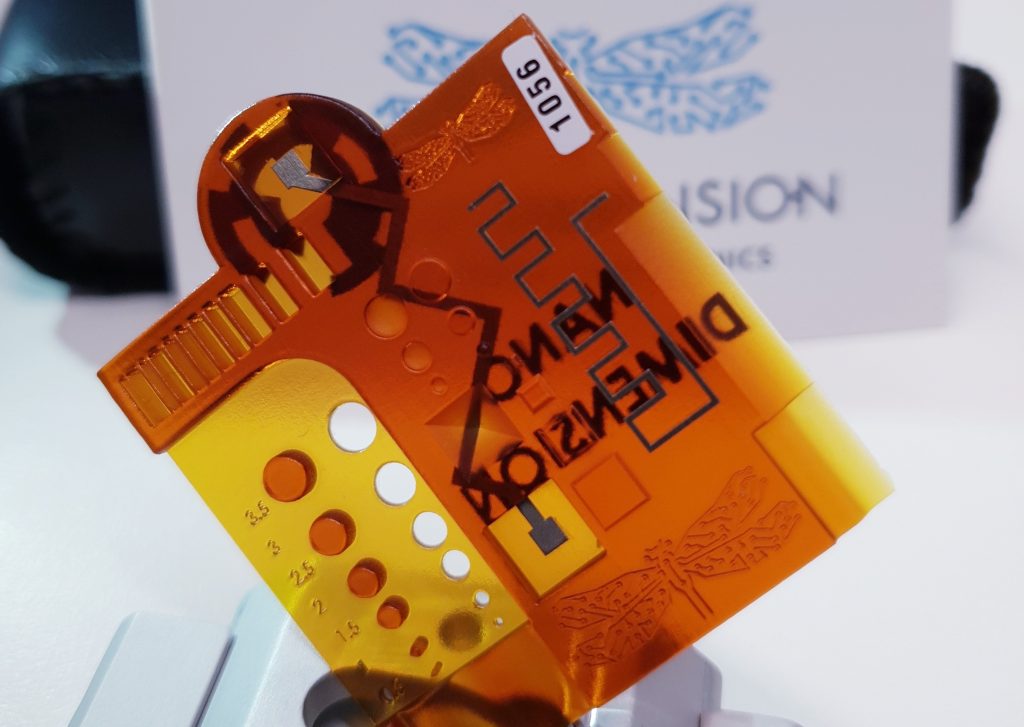

In late-November 2021, Nano Dimension launched the latest version of its electronics 3D printer, the DragonFly IV. The 160 mm x 160 mm x 3 mm system is said to enable the production of custom multi-material, multi-layer circuits in a single step, including substrate, conductive traces, and passive components.

This process is facilitated by the Flight software launched alongside the DragonFly IV, which features intelligent verification, slicing and job control functionalities that allow for the 3D modeling of sophisticated parts. 3D printing with Nano Dimension’s newest machine is also guided by the deep learning algorithms of DeepCube, in a way that improves users’ yields and enables real-time print correction.

According to the company, it has already sold DragonFly IVs to national armies, navies, air forces, and governmental intelligence agencies, across Europe. When it comes to its latest sale, Nano Dimension’s VP of EMEA Sales, Stephan Krause, says the technology is set to help its customer “shorten its development cycles and bring to life innovative ideas which could not have been done before.”

Nano Dimension has no doubt established itself in the electronics 3D printing sector, but it’s far from the only firm operating in the space. nano3Dprint launched its new A2200 electronics 3D printer earlier this month, complete with an upgraded printhead, paste deposition mechanism and built-in video monitoring system.

Elsewhere, on a more experimental level, InnovationLab has made an electronics 3D printing breakthrough. As part of the ‘SmartEEs2’ EU Horizon 2020 project, the firm has developed a process that enables the production of solderable copper circuits, while using less energy than traditional methods and avoiding the need for toxic etchants.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Nano Dimension’s DragonFly 3D printing technology. Photo via Nano Dimension.