Researchers at sustainable meat developer Steakholder Foods and the National University of Singapore (NUS) have announced significant advances in their respective food 3D bioprinting initiatives.

NUS scientists have come up with a plant-based bio-ink that fully absorbs into meat products and can also be produced from food waste, in a way that could help drive down the cost of creating new lab-made foods. Steakholder, meanwhile, has been awarded $1 million by the Singapore Israel Industrial R&D Foundation (SIIRD) to developed a bioprinted eel alongside fellow cell culturing innovator, Umami Meats.

“Industry collaborations are a critical aspect of our long-term business strategy,” said Yair Ayalon, VP of Business Development at Steakholder Foods. “Our partnership with Umami Meats is especially meaningful following our recent patent application for fish texture and because it is being supported by a joint Israeli/Singaporean government initiative of which we are very proud to be a part.”

Identifying a cheaper artificial meat

Generally speaking, cultured meat is made using stem cells taken from animal muscles and seeded onto a tissue scaffold, designed to facilitate their growth. In lab-based studies, such meat replacements continue to show promise as a more humane alternative to attaining meat via livestock farming, but cost remains a factor in their low market adoption.

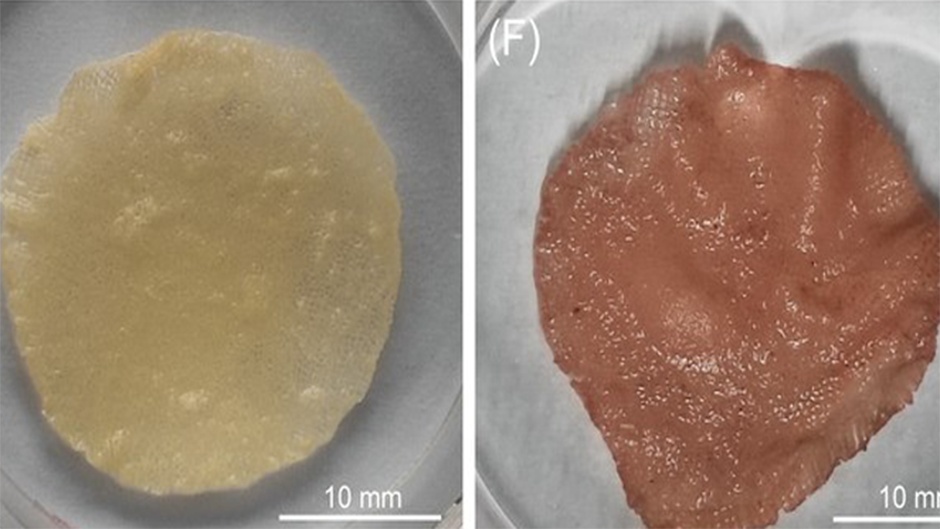

To address this, NUS and Xi’an Jiaotong-Liverpool University researchers have created a new plant-based bio-ink. Derived from food waste such as cereal husks, the team’s material is designed for integration into biodegradable scaffolds which are cheap enough to facilitate the large-scale manufacture of cultured meat.

By mixing cereal proteins extracted from barley or rye with corn protein to produce pure cereal protein-based inks, the scientists say it could also be possible to “alleviate the pressure on the environment from animal agriculture.”

“This is a novel and disruptive idea to mass produce cultured meat,” said study co-author Professor Jie Sun. “We have optimized our plant-based ink for 3D printing technology so that we can print scaffolds and place muscle stem cells on them. The cells can then grow with the structure of the scaffold and we use beets to colour the grown meat to give it the look of conventional meat.”

More information about the researchers’ efforts can be found in their paper titled: “3D-Printed Prolamin Scaffolds for Cell-Based Meat Culture.”

Next up, edible 3D bioprinted eel?

In another bioprinting-led initiative, Steakholder and Umami Meats have been awarded $1 million by the SIIRD, a cooperation between Enterprise Singapore (ESG) and the Israel Innovation Authority (IIA), to develop an artificial eel food substitute.

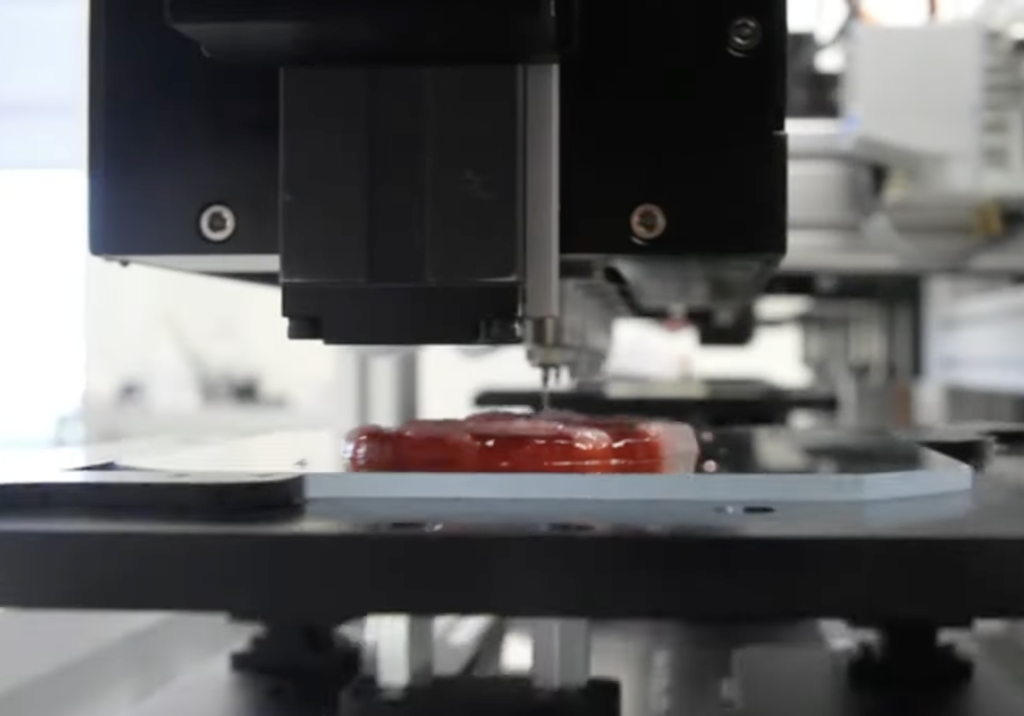

In-house, Steakholder has already developed a means of 3D bioprinting meats from animal stem cells. During this process, a proprietary bio-ink is said to be “printed into whole cut of meat with pinpoint precision based on a digital design.” These are then incubated to allow their component stem cells to differentiate into muscle and fat, and for fibers to form the density, thickness and length for cooking.

For its part, Umami Meats has also been working on a way of creating seafood from stem cells for some time, with the goal of developing an edible alternative to fishing for tuna, eels and other marine life. In the past, the firm has taken steps towards this by signing an MoU with MeaTech 3D, another 3D bioprinting specialist seeking to pave the way for meat replacements in Singapore.

Working with Steakholder, Umami Meats now plans to take its efforts in the country a step further, by developing a scalable process for the manufacture of structured cultivated fish products. It’s said that the former intends to deploy a new technology it has developed to create foods that mimic the flaky texture of cooked fish, with a prototype ‘hybrid product’ expected to be ready later in Q1 2023.

“We are thrilled to be combining our deep knowledge and experience in cultivated seafood with Steakholder Foods’ innovative 3D bioprinting technology,” said Mihir Pershad, CEO and Founder of Umami Meats. “We believe this partnership will help us advance our vision of a new, more sustainable food system for preserving our marine ecosystems while delivering exceptional, high-quality seafood.”

3D printing’s role in vegan-friendly meat

As efforts to minimize livestock farming continue to gain traction, research into 3D bioprinting meat alternatives is beginning to gather momentum and a significant amount of backing. In December 2021, Redefine Meat’s commercial roll-out in Europe saw its plant-based 3D printed meat products offered at high-end restaurants across the continent.

More recently, Japanese precision instrument manufacturer Shimadzu has announced plans to establish a meat 3D printing production line. Working with Osaka University and Sigmaxyz Inc, the company is said to be developing a machine capable of churning out large quantities of cultured meat, with the aim of putting it into practice by 2025.

CellMEAT’s Dokdo cultured shrimp is also set to hit the US, Korean, and Singaporean markets by 2024. Fresh off the back of an $8.1 million Series A funding round in April 2021, the firm announced plans to establish a production facility in Seoul that could be capable of producing as much as 100kg of cultured shrimp per day.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a meat substitute being produced using Steakholder’s 3D bioprinting process. Photo via Steakholder.