Japanese precision instrument manufacturer Shimadzu is currently honing an automated meat 3D printing system, according to a Nation Thailand report.

Working with Osaka University and consultancy firm Sigmaxyz Inc, Shimadzu is said to be developing a machine capable of churning out large quantities of cultured meat, in a production line-style set up. Through the project, the company is aiming to come up with a way of producing meat alternatives by 2025, that yields edibles which not only replicate the texture of the real thing but taste better too.

Shimadzu’s meat-printing ambitions

Founded in Kyoto back in 1875, Shimadzu is better known as either a manufacturer of analytical, testing and measuring instruments, or a producer of industrial and aircraft gear, than it is for its 3D printing exploits. Despite this, the firm is now reported to be pursuing the idea of growing artificial meat from animal cells, as a means of developing a cruelty-free alternative to killing and eating livestock.

Although the nature of the meats Shimadzu is attempting to create hasn’t been revealed, it’s believed that they’ll largely be produced via a technology honed at Osaka University. Using this process, it’s said to be possible to layer cells into tissues such as muscle, fat and blood vessels, before bunching them together to form fibers that resemble real meat.

What’s more, the technology is even reported to be capable of manufacturing ‘marbled’ meat, which in the case of the genuine article, means that it includes white flecks of intramuscular fat that provide it with extra tenderness and flavor.

By integrating this Osaka-developed process into an automated unit, it’s said that Shimadzu believes it possible to grow cells into structures, before testing them for taste and texture on an ‘assembly line.’ While the firm is also considering applying the technology in the fields of regenerative medicine and drug R&D, for now, it’s focused on having meat samples ready to serve at the Osaka-Kansai Expo 2025.

Osaka University’s Wagyu experiment

Shimadzu may not have laid out the full process behind its planned meat printing set up just yet, but it could well be related to the approach developed at Osaka University last year. In the project, which was carried out alongside printing specialist Toppan, researchers managed to 3D print marbled Wagyu beef in a way that was said to be unique, in that it closely-replicated the meat’s natural texture.

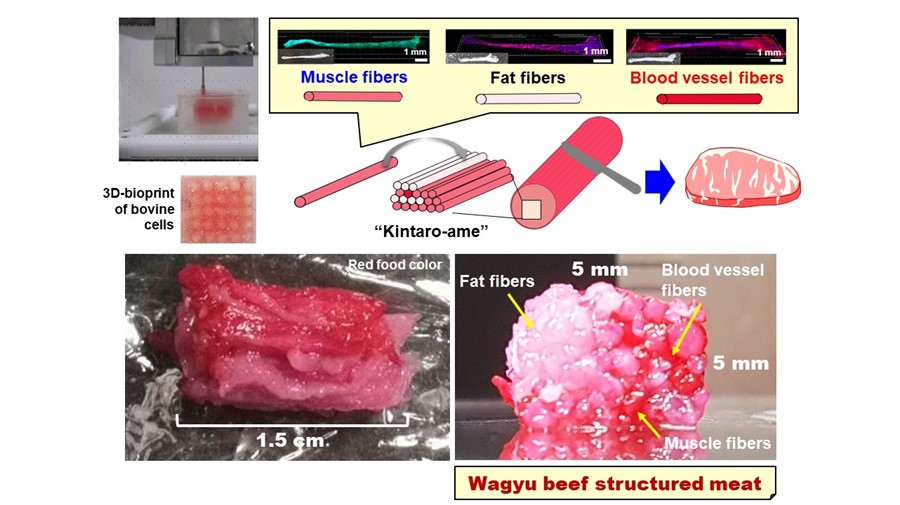

To achieve this, the Osaka team came up with something they called ‘tendon-gel-integrated bioprinting’ or ‘TIP,’ in which tendon-like gels could be built up layer-by-layer into steak shaped structures. Interestingly, the scientists’ technique also allowed for different tissue types to be integrated into the same foodstuff, which ultimately enabled them to better reproduce real meat equivalents.

Once the researchers had honed their method, they deployed it to recreate samples of everyday Wagyu beef they’d imaged and modeled. By layering a set of 72 bovine cell fibers, including those designed for building muscle, adipose and capillaries, the team found they were able to do so while defining the resulting meat’s texture, and they theorized it could even be used to adjust fat content.

At the time, the Osaka-based scientists suggested that their process had the potential to help undo some of the environmental damage caused by livestock farming, yet since they made their breakthrough, which was covered on news sites around the world, not much has been heard from the Wagyu innovators, suggesting that it may have been little more than a flash in the pan.

In light of developments at Shimadzu, however, it’s now possible (although unconfirmed) that TIP 3D printing could be industrialized and brought to market. Alternatively, if Shimadzu’s project does turn out to be based around a different 3D printing approach, it wouldn’t be surprising as the technology has taken huge strides over the last 12 months alone, and it continues to make iterative advances.

Coming soon to a store near you?

While 3D printed meats may not be ready to pick up at your local supermarket just yet, the technology behind their production continues to make progress that suggests this may not be a million miles away. Late last year, MeaTech announced that it had broken new ground, by managing to 3D print an entire 3.67 oz steak at its lab in Ness Ziona, Israel.

Since then, researchers at China’s Zhejiang University have taken things in a different direction, developing a way to 3D print meat from plant-based gels. The team’s soy protein, pea protein and wheat gluten-sourced food, is said to provide a similar level of nutrition to actual meat, without incurring the same health and sustainability-related costs.

Over in Barcelona, Novameat has also come up with a fresh approach to meat production recently, involving the 3D printing of blue algae into steaks. Concocted from animal cells, plant-based derivatives, fungi and algae, as well as spirulina, a specific type of algae known for its high protein, the firm’s blue steak is designed to push the limits of the technology, thus it’s unlikely to ever make it to market.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

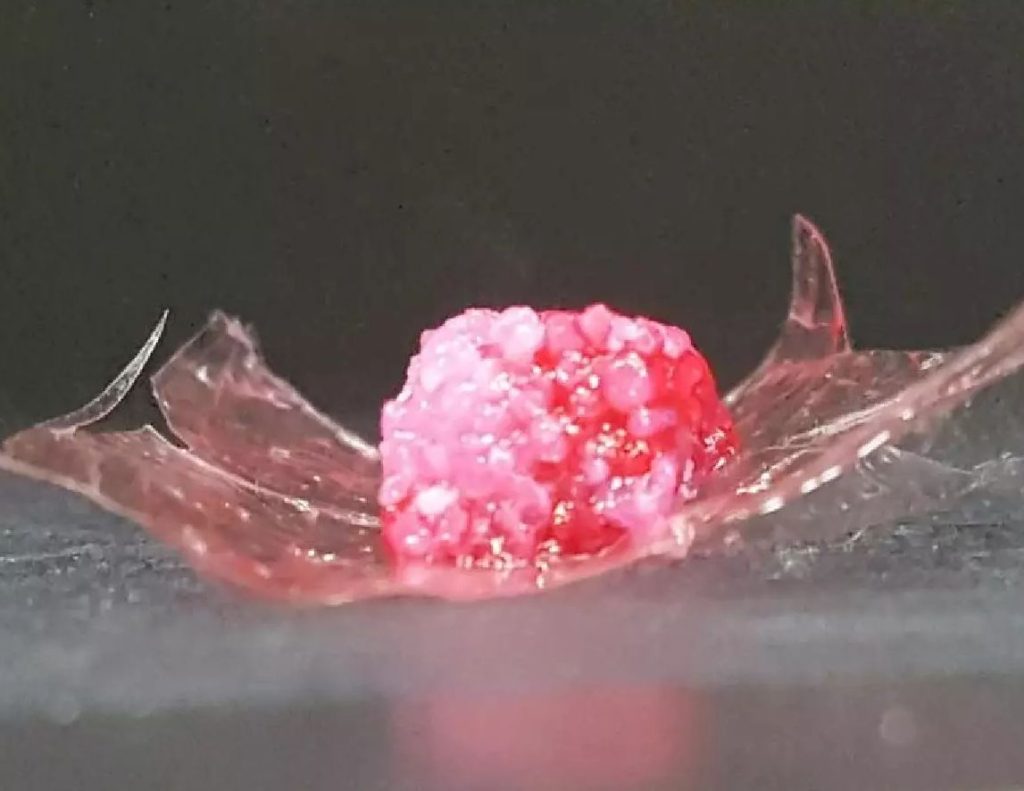

Featured image shows a meat sample produced using Osaka University’s 3D printing technology. Image via the Nation Thailand news site.