Chinese 3D printer manufacturer Creality has raised HK $33 million ($4.3m USD) in Kickstarter funding for its upcoming CR-6 SE 3D printer.

The company crowdfunded one of its systems for the first time in an attempt to gauge interest and involve the 3D printing community within the system’s R&D cycle. Creality’s Kickstarter campaign has already become one of the most successful on the platform this year, despite having only run for one month.

Speaking to 3D Printing Industry, Jack Chen, CEO, and Founder of Creality expressed his excitement about the future of the CR6-SE 3D project.

“We’re very proud of the HK$ 33 million we have raised so far from the Kickstarter campaign, and I would like to thank all those that are taking part,” said Chen. “It’s remarkable how much support has been generated by the project in just one month, and the funding makes Creality the number one printing project on the Kickstarter platform for 2020.”

“I would encourage all creators to continue getting involved in the project, as it will enable us to develop the best 3D printer possible.”

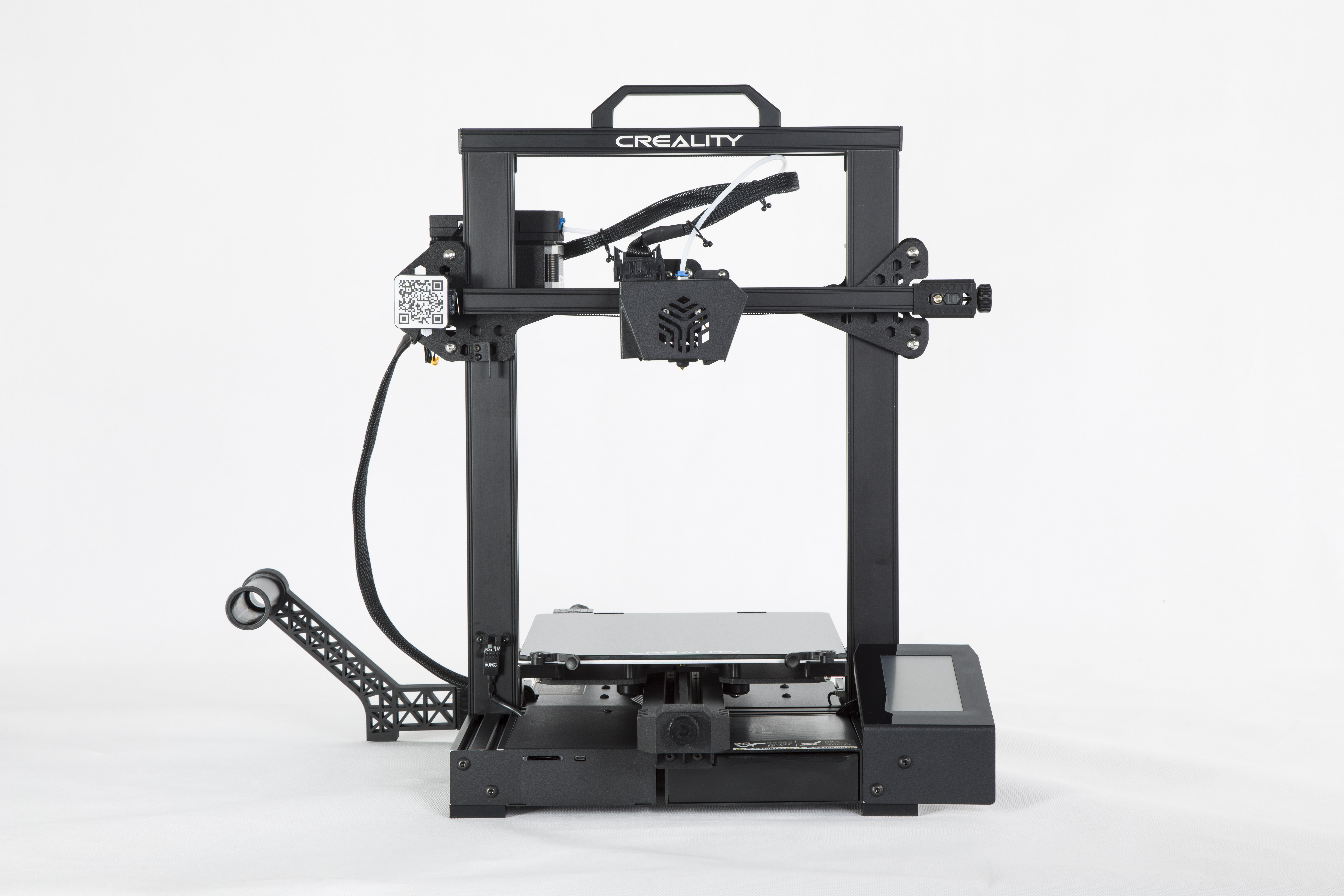

Creality’s CR-6 SE 3D printer

Creality’s user-friendly focused CR6-SE Fused Filament Fabrication (FFF) system is aimed at hobbyists and newcomers to the world of 3D printing. The CR-6 SE features a modular aluminum body, with sealed dust-resistant coupling points, which can be disassembled and packed away for transportation. The printer is ready to use right out of the box and can be put together and made operational in just five minutes.

The system contains several attributes that make it suitable for first-time adopters. Bed leveling can often be a problem with consumer-grade machines, leading to nozzle clogging, poor adhesion, and generally low quality of prints. Creality’s new 3D printer has a built-in “leveling-free device,” which utilizes a smart pressure sensor to constantly and automatically level the bed, so the user doesn’t have to.

“Our newest system offers a range of features that have been developed with the newcomer in mind,” said Chen. “Levelling the printer’s bed properly can be a challenge for new adopters, but with our innovative True Leveling-Free Technology, users can always rely on highly-accurate results.”

Poorly designed printhead assemblies can also cause nozzles to clog or ooze during 3D printing. The CR6-SE combats this with a redesigned modular printhead structure which allows users to replace and substitute components with ease. Creality’s machine also encourages experimentation, and its heat sink, heat block, Teflon tubing, and hotend are all deconstructable.

The CR6 SE features a simplified interface with a 4.3 inch HD Color LCD Touch Screen, which allows users to easily and intuitively operate the device. As an all-in-one DIY solution, Creality’s new 3D printer enables the creation of products ranging from prototypes to complex tools and devices. As a result, the system allows both experienced hobbyists and newcomers to create final products with a high level of precision down to just 0.01mm.

The Creality CR6 SE Kickstarter project

Creality chose to use Kickstarter to fund the CR6 SE due to the platform’s position as a global leader in launching community-led projects. The company followed the progress of other 3D printing campaigns on Kickstarter and observed that backers were often vocal with their feedback. Later, in May 2020, Creality launched its own campaign in an attempt to engage these creatives within the research and development of its own systems.

“Kickstarter is a global leader in the community and it has gathered a great deal of intelligent and creative people together,” said Chen. “The 3D printing community has a lot to offer in terms of product feedback, and we hope that our backers will continue to play an active role in the R&D of the CR-6.”

As the printer’s user base grows, the company aims to build a “long-term, deep, and healthy interaction” with early adopters. Creality has said that it accepts that community input often involves challenges as well as suggestions, but maintains it can iteratively implement user feedback into the CR-6 SE. Moreover, with the project’s initial machines priced at $265, the firm is marketing its system to the broadest possible audience in order to maximize the benefits of its approach.

Creality’s record-breaking campaign

Building on its feedback-based development cycle, the Creality CR-6 SE has already been the subject of multiple Youtube reviews. Many of the popular Youtubers’ channels have millions of subscribers, which could increase the potential of attracting new adopters. Creality’s new 3D printer has also undergone the Autodesk Kickstarter Test, which showcases the capabilities of new systems to backers on the platform.

The system scored an impressive 26.5 out of 30, including full marks for preventing overhangs, bridging, and fine negative features. As a result, the reception from the Kickstarter community has so far been extremely positive for the CR-6 SE. Not only has the machine been backed by more than 10,000 supporters, but it’s broken many of the website’s records too.

Creality’s new machine is now this year’s most popular and best-funded 3D printing project on Kickstarter, and the second-highest printing-related campaign in the platform’s history. At present, the company is dispatching orders for an August 2020 delivery date. To date, the firm has shipped more than 2,000 3D printers to customers, around 48 percent of those that backed the project with full purchase.

“Creality is a brand that customers can trust to deliver robust, affordable, and easy-to-use 3D printers,” concluded Chen. “The CR-6 SE will be the latest in a long line of successful Creality FDM systems, and with feedback from our loyal user base, who knows what we can achieve.”

Creality in the 3D printing industry

Creality is known within 3D printing for its entry-level desktop 3D printers, and it’s level of engagement with the hobbyist community. Over the years, the company’s affordable, accessible systems have proved to be compatible with components produced by a range of other 3D printing firms.

Swedish extruder developer Bondtech released a Direct Drive System (DDS) that was developed in collaboration with the 3D printing community. DDS combines the Bondtech Mini Geared (BMG) extruder with E3D’s V6 hotend to enable improved control in Creality’s CR-10S system.

E3D Online also used the hotend it had developed for its Supervolcano line of 3D printers on a Creality CR-10 S5. The part was found to be interchangeable, and the company used the Creality machine to produce jigs and fixtures for its assembly lines.

Due to their ease of use, Creality’s systems have also been adopted by different groups of researchers. Scientists at Canada’s Université Laval used an ENDER-4 system to 3D print a type of glass that was suitable for incorporation into lasers and infrared optics. Researchers from the University of Nantes meanwhile, leveraged a Creality CR-10 machine to investigate the heat transfer and adhesion between layers in FFF 3D printing.

You can now nominate for the 2020 3D Printing Industry Awards. Cast your vote to help decide this year’s winners.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

Looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows someone using a Creality CR6-SE 3D printer. Image via Creality.