In alliance with Airbus Defence & Space, AddUp has developed a metal 3D printer intended for space applications under the European Space Agency (ESA) contract.

Co-funded by Airbus Defence & Space, this system is designed to evaluate additive manufacturing capabilities and performance in sustained microgravity conditions. The metal 3D printer was launched toward the International Space Station (ISS) by NASA Mission NG-20 on January 30, 2024. As a part of the “Metal3D” project, this system is set to undergo testing aboard the Columbus module of the ISS. According to Airbus, operational printing is expected to begin in late February or early March.

AddUp’s Technical Director, Sébastien Devroe said, “The development of the Metal 3D printer relies on the unique multidisciplinary expertise of AddUp’s engineers and researchers. Our staff has expertise across a variety of additive manufacturing processes, machine design, programming and operation optimization. Our teams have supported the development of this first space metal 3D printer, which will soon be in orbit. The metal 3D printer has been designed and optimized to meet the conditions and environment of the International Space Station.”

Testing the feasibility of metal 3D printing in space

The “Metal3D” project commenced in 2016 when Airbus Defence & Space was awarded the contract by ESA. The primary aim was to engineer a metal 3D printer capable of functioning under microgravity conditions aboard the ISS.

While polymer 3D printers have been operational on the ISS since 2014, enabling astronauts to fabricate and replace plastic parts, the introduction of a metal 3D printer opens up new possibilities. According to Airbus, the logistical challenge of supplying equipment to space stations will become more noticeable in future lunar and Martian missions. The ability to manufacture parts in space could significantly reduce reliance on Earth-based supply chains.

However, the transition from terrestrial to space-based metal 3D printing presents unique technical hurdles. Sébastien Girault, Airbus metal 3D printer System Engineer, outlines two primary challenges. Firstly, miniaturizing the printer to fit the ISS’s constraints, scaling it down from the typical ten-square-meter size to that of a washing machine.

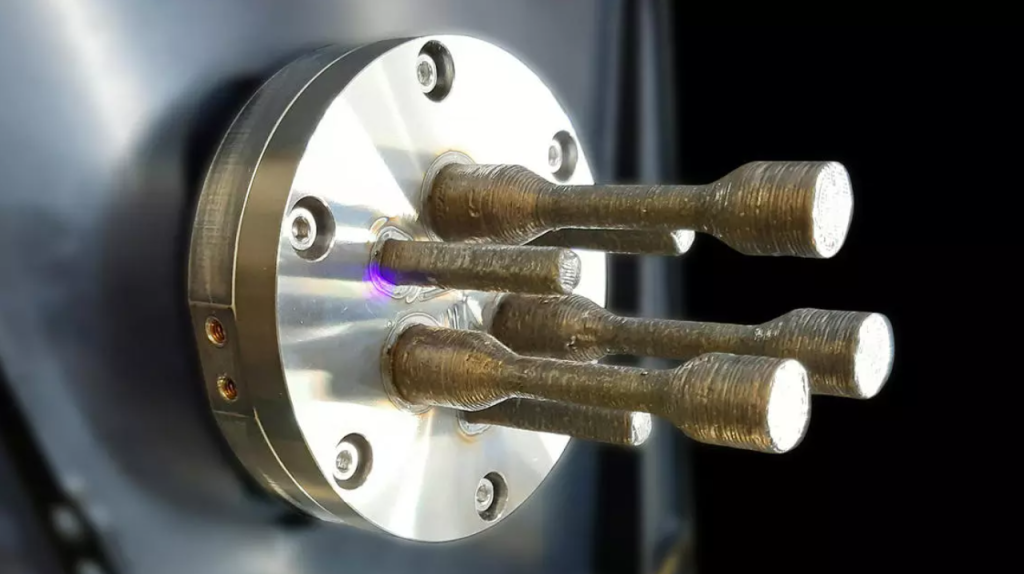

Secondly, ensuring safety by enclosing the printer in a sealed metal box due to the high heat generated by the laser, with metal alloys having a much higher melting point exceeding 1,200°C, compared to plastics at around 200°C, necessitating stringent thermal control. Additionally, Girault emphasizes the importance of gravity management, opting for wire-based printing to mitigate gravitational effects, unlike powder-based systems.

On-demand manufacturing in space

The upcoming experiment will involve the deployment of two 3D printers: a “flight model” aboard the ISS and an “engineering model” on Earth. Astronauts will print four samples in space, which will be returned to Earth for analysis alongside specimens produced using the engineering model. Mechanical strength, bending tests, and microstructural analysis will be conducted to evaluate the effects of microgravity on the printed parts.

Airbus anticipates that metal 3D printing on the ISS will improve the understanding of the quality of metal printing in space and provide valuable insights into operating such printers in extraterrestrial environments. According to the company, this technology is a crucial step towards establishing a sustainable human presence on the Moon and beyond.

“In order to evaluate the effects of microgravity, ESA and Danish Technical University will perform mechanical strength and bending tests and microstructural analysis on the parts made in space and compare them to the other specimens,” added Girault.

3D printing elevates space manufacturing

The use of additive manufacturing for space applications has gained traction in recent years. 3D printing in space offers the potential for resource-efficient manufacturing, increased adaptability, and cost reduction in space missions. A notable example of AM in space includes the 3D bioprinting a human knee meniscus on the ISS by Redwire using its upgraded 3D BioFabrication Facility (BFF).

The printed meniscus returned to Earth on SpaceX‘s Crew-6 Mission for analysis after 3D print operations in July last year. This achievement aims to improve treatments for meniscal injuries, particularly common among US Service Members and was conducted as part of the BFF-Meniscus-2 Investigation with the Uniformed Services University of the Health Sciences Center for Biotechnology (4D Bio3). NASA astronauts Frank Rubio, Warren Hoburg, and Stephen Bowen, alongside UAE astronaut Sultan Al Neyadi, conducted this ISS-based investigation.

As part of the AstroCardia project, a consortium of Belgian companies and research centers have collaborated to send a 3D printed ‘heart-on-a-chip’ to the ISS. Scheduled for orbit in 2025, the 3D bioprinted artificial heart and circulatory system are being developed by Space Application Services, SCK CEN, QbD Group, BIO INX, and Antleron. This initiative aims to enable scientists to enhance their understanding of the heart’s aging process, as the organ undergoes aging 20 times faster in zero-gravity conditions.

What are the 3D printing trends the industry leaders expect to see this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the world’s first metal 3D printer for space is on its way to the ISS. Photo via Airbus.