Australian large-format 3D printer manufacturer AML3D has signed a contract with Toolcraft Australia to supply a 6-part nozzle assembly for an Australian Government’s Defense Science and Technology Group (DSTG) project, valued at AUD$0.35 million.

After successfully delivering a 4-stage nozzle assembly, highlighting the benefits of its Wire Additive Manufacturing (WAM) technology with its faster production times compared to traditional methods, AML3D has now expanded the contract to include an additional 2 stages of an Aluminium ER5183 nozzle assembly. These additional stages are anticipated to be sizable, weighing approximately 1230 kgs and measuring over 3.6 meters in length.

Following the proven operational superiority of previously produced AML3D WAM 4-stage nozzle assembly components, the manufacturing process for 6-part assembly is scheduled to start promptly. Delivery of the first two stages is anticipated within the current financial year, with the remaining four stages expected in FY25.

“We are extremely pleased to continue to expand on our previous work supporting the DSTG. It is a strong endorsement of AML3D’s WAM technology for defense applications to have the scope of this [AUD]$0.35 million contract expanded to 2 additional nozzle segments that had previously been traditionally manufactured. AML3D’s ability to use our proprietary WAM technology to produce higher quality components, with significantly faster turnaround times, compared to traditional manufacturing, and with less waste allows us to play an increasingly important role in defense supply chains,” said AML3D CEO Sean Ebert.

AML3D expands on defense capabilities

Beyond this contract, AML3D has achieved success with a notable presence in the US defense sector, thanks to its ‘Scale up’ strategy, which delivered approximately AUD$12 million in contracts last year. The company’s strategic focus includes penetrating further into defense markets, and this contract serves as a step toward achieving its medium-term growth objectives.

As a part of AML3D’s ‘Scale up’ strategy, an ARCEMY ‘X-Edition 6700’ 3D printer, worth AUD$1.1 million, was deployed at the US Navy’s Additive Manufacturing Center of Excellence in Virginia last month. This move addressed supply chain challenges in the U.S. Department of Defense (DoD), especially within the Navy’s submarine industrial base. Acquired through Phillips Corporation, the printer marks a significant milestone in AML3D’s partnership with the DoD, aiming to strengthen domestic supply chains amid global uncertainties.

On another note, AML3D extended its contract to test Nickel-Aluminium-Bronze (NAB) alloys for the US Navy’s submarine program. This follows successful prior testing and validates the compatibility of AML3D’s ARCEMY 3D printed alloys with the US Navy standards. The extension aligns with AML3D’s strategy to integrate ARCEMY technology into the submarine industrial base. It also coincides with heightened interest in advanced manufacturing due to the AUKUS alliance, positioning AML3D well in the US and allied defense markets, said Ebert.

Elsewhere, AML3D sold an industrial ARCEMY ‘X-Edition 6700’ metal AM system to aid the US Navy‘s implementation of WAAM technology, facilitated by US DoD’s intermediary BlueForge Alliance. Valued at approximately AUD$1.0 million, this system was housed at Oak Ridge National Laboratory (ORNL).

Forging a stronger defense sector

The evolving use of metal AM holds immense potential for creating a more agile, efficient, and adaptable defense sector.

In line with this, Bechtel Plant Machinery Inc. (BPMI) selected Velo3D’s metal AM system for the U.S. Naval Nuclear Propulsion Program. Using Velo3D’s Sapphire XC printer, operated by materials company ATI, the system is aimed at streamlining part production, reducing lead times, and enhancing supply chain efficiency. The Navy anticipates improved maintenance capabilities through AM integration, signaling improvements in complex part production, and unlocking new opportunities in the defense and aerospace sectors.

Australian defense contractor BAE Systems partnered with AML3D to explore 3D printing metal parts for the Royal Australian Navy‘s nine Hunter class frigates. Certified by Lloyd’s Register and DNV, AML3D’s technology offers high-strength, custom-designed components with faster production times. This collaboration strengthened both companies’ positions in the marine and defense sectors, specifically supporting BAE Systems Australia’s shipbuilding projects.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

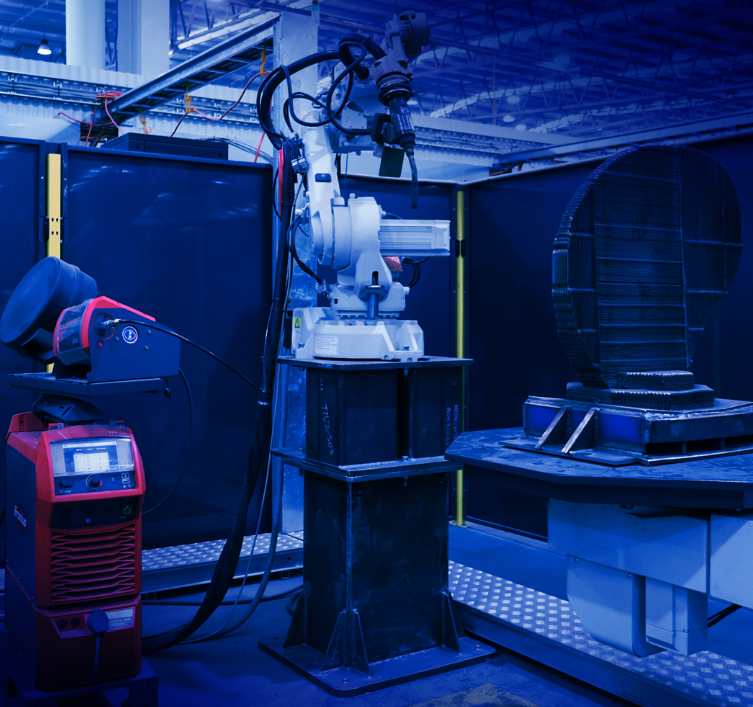

Featured image shows a typical ARCEMY metal 3D printing system. Image via AML3D.