Furniture and interior design company Steelcase, in collaboration with Skylar Tibbits’ Self Assembly Lab at MIT, has unveiled a new method of 3D printing termed “rapid liquid printing”. The technique is under development to provide a process that competes with the speed, size, and materials available to existing 3D printing methods. In doing so, Steelcase hope to unlock the potential of truly personalized interior design.

Defying gravity

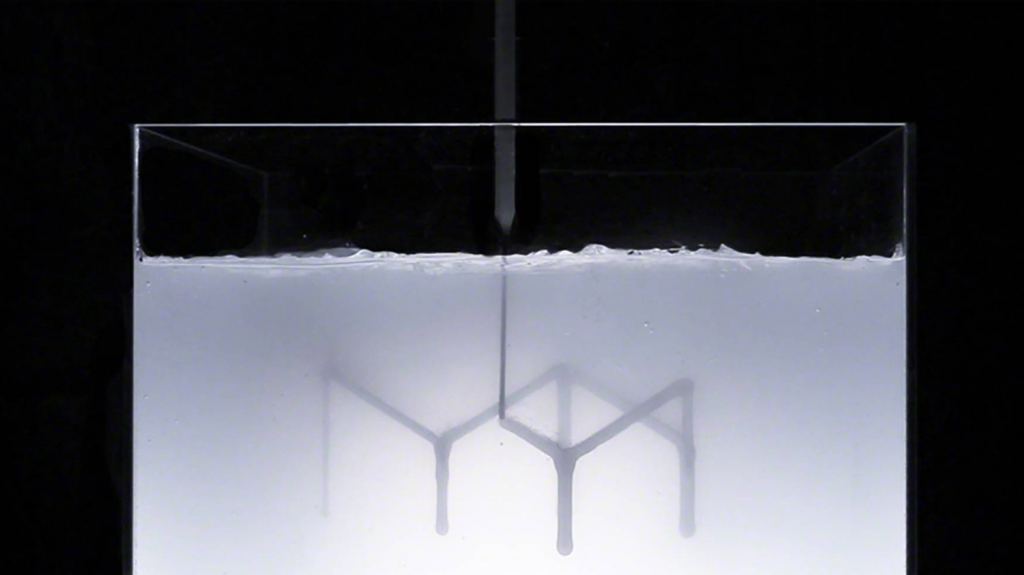

In contrast to the typical approach where materials are extruded in layers to create a 3D object, rapid liquid printing defies gravity by depositing materials in a viscous gel that serves as a support. Once the material, such as rubber, is “drawn” into the gel to make the desired shape, it is chemically-cured into a solid.

The flow of this process enables large structures to be 3D printed in a fraction of the time it would take in other methods. The top of the Bassline table, seen in the photo below, was rapid liquid printed in just 28 minutes, requiring little to no post-processing other than attachment to the legs.

Cutting edge design

The method was presented by product designer Christophe Guberan at Milan Design Week. As previously reported on 3D Printing Industry, Salone del Mobile Milan has been a hub of 3D printed architectural designs with projects from Zaha Hadid Architects and MIT’s Neri Oxman.

Yuka Hiyoshi, turnstone senior industrial designer at Steelcase, comments on the new method saying,

As a designer, what’s most fascinating and unique about Rapid Liquid Printing is the line quality of the print. It’s soft, almost organic. It evokes images of brushstrokes or the branches of plants.

RapidLiquidPrinting from Self-Assembly Lab, MIT on Vimeo.

Suspended in gel

Another 3D printing method to use a vat of gel as support for a liquid ink is in the Picsima 3D printer from Fripp Design. This patented technology from the UK based design agency uses a vat of silicone to create objects such as realistic prosthetic eyes.

For direct-write 3D printing of materials as flexible as silicone, Munich-based Wacker Chemie is one company looking into the process. Another study from researchers in Singapore and Israel claims to have created the “most stretchable” 3D printable material for use in SLA and CDLP.

For more news on the latest 3D printing methods sign up to the 3D Printing Industry newsletter, and follow our active social media sites.

Don’t forget to vote in the first annual 3D Printing Industry Awards.

Tickets for the 3D Printing Industry Awards are also now available here.

Featured image: A rubber structure 3D printed using the rapid liquid printing method from Steelcase and MIT