The 2021 3D Printing Industry Awards shortlists are now open for voting until the 20th of October. Cast your votes here.

Sculpman, an engineering startup based in Belgium, has announced its new patented ‘Variable Nozzle Technology’ to advance extrusion-based 3D printing.

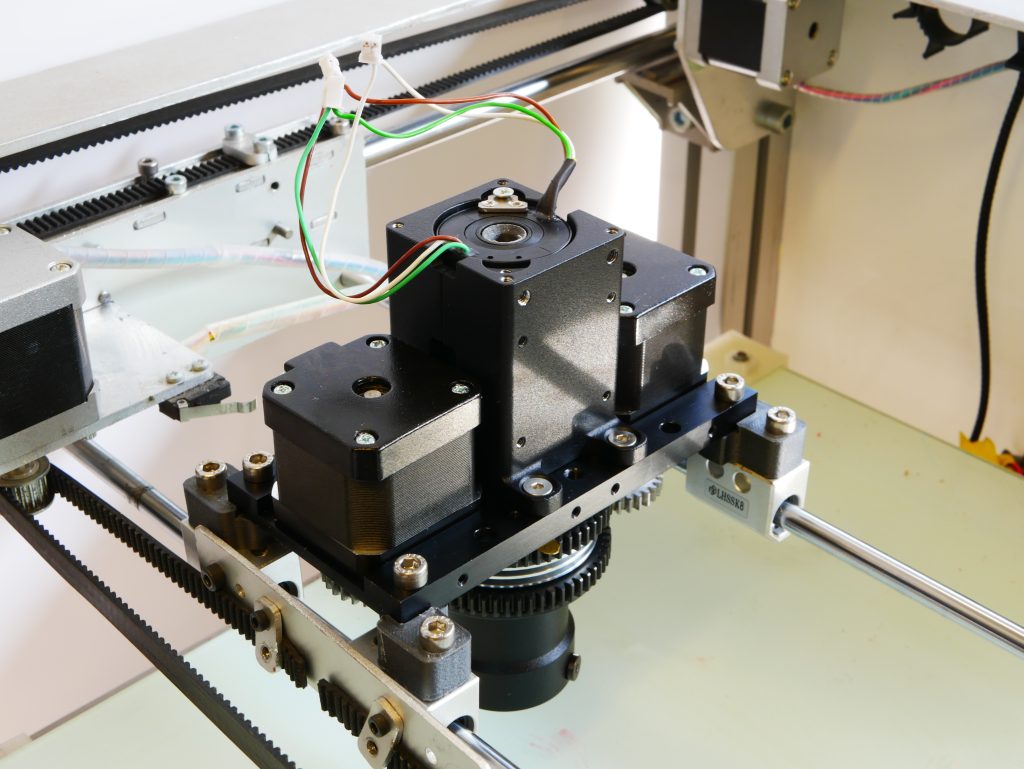

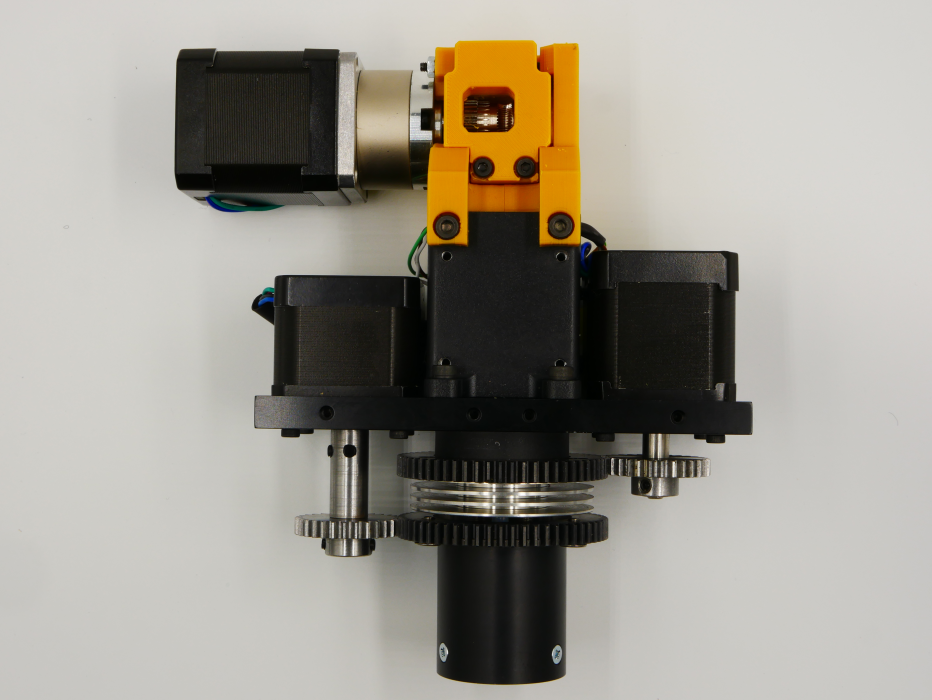

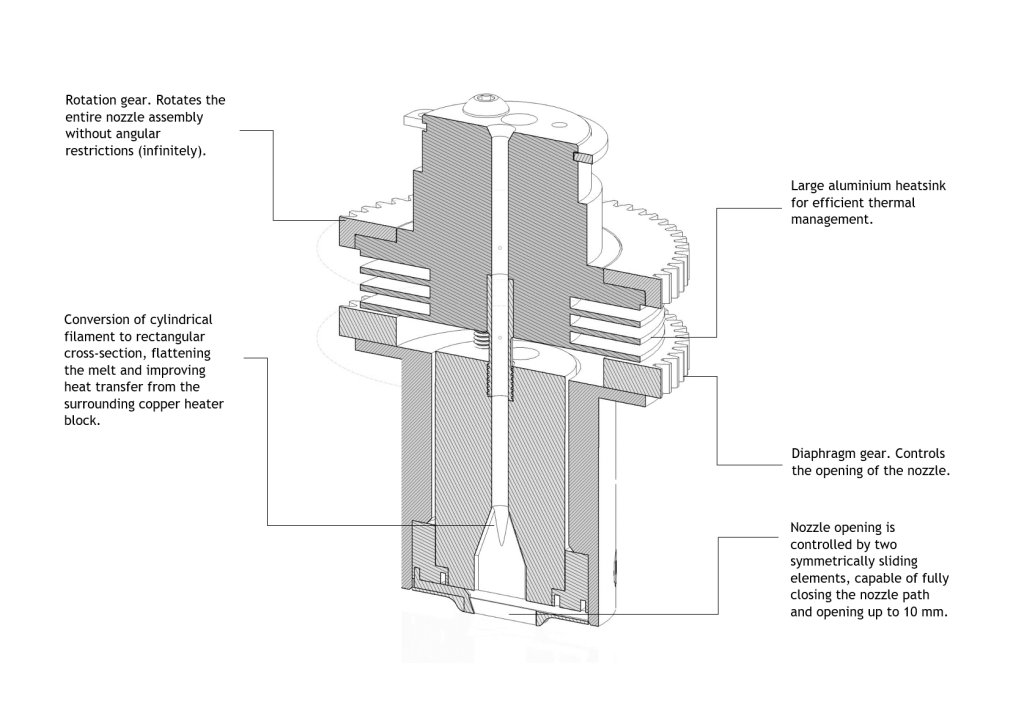

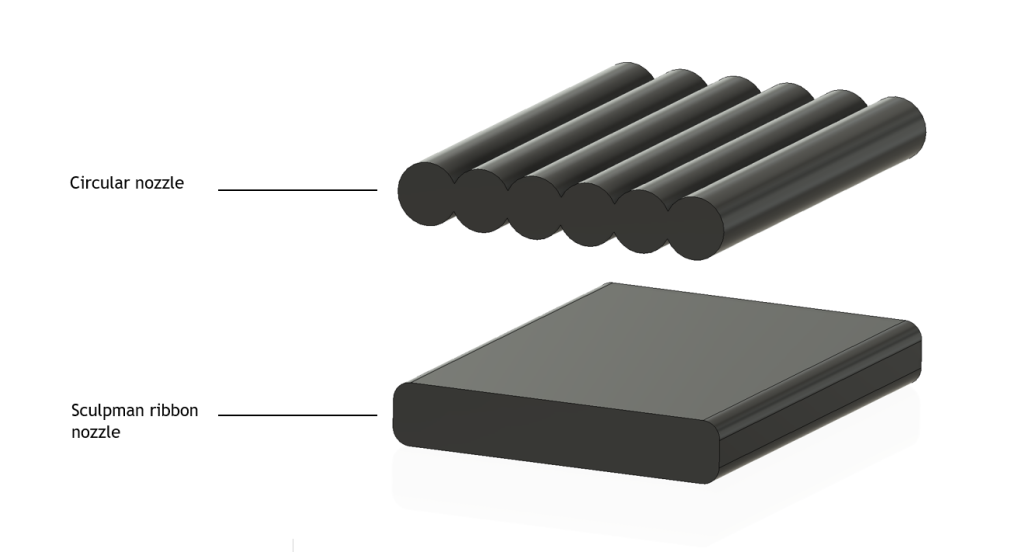

Backed by two years of research and development, the firm’s novel printhead product aims to combine speed and precision like never before. It works by discarding the conventional fixed-size circular nozzle shape, which has been the standard in FDM 3D printing since its invention, instead opting for a continuously variable opening that deposits flat tracks up to 10mm in width.

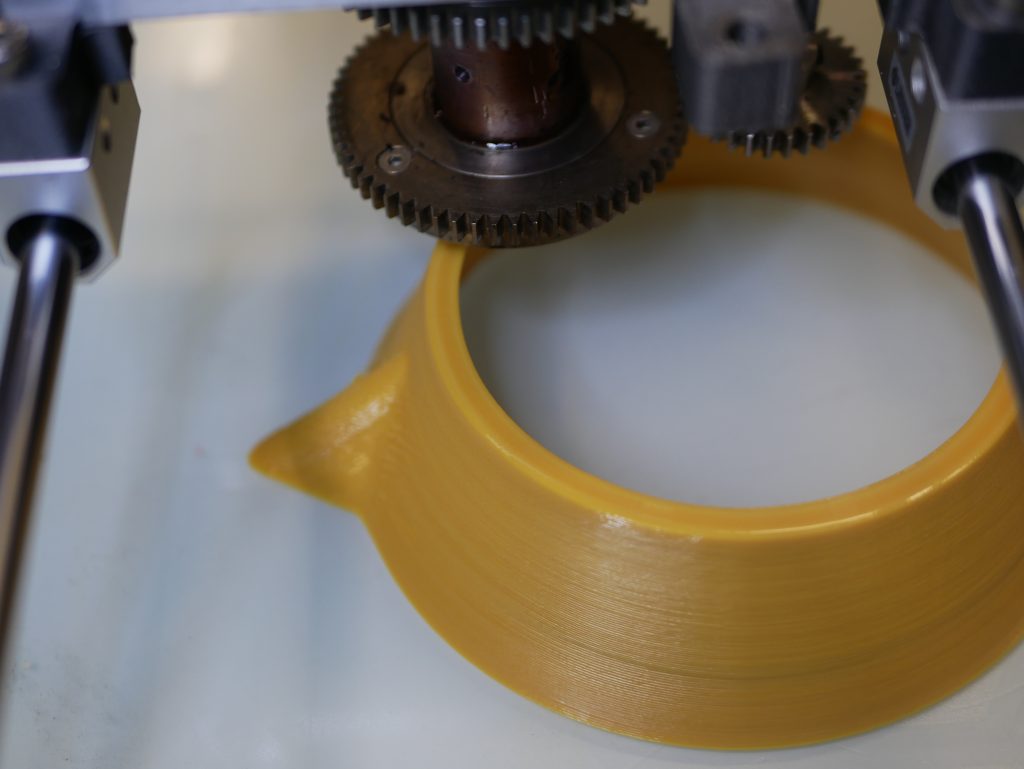

According to Sculpman, its proprietary innovation can 3D print strong and precise polymer parts at previously unseen throughputs, cutting print times down from hours to a matter of minutes.

Limitations in FDM 3D printing

Material extrusion is the most widely used 3D printing technology, owing to its ease of use, accessibility, and ever-increasing material compatibility. In recent years, the process has been utilized for applications such as high-strength automotive tooling, non-critical aircraft components, and even end-use rolling stock parts. As well as basic polymers like PLA and ABS, material extrusion can now make use of technical and engineering-grade thermoplastics like PEEK, and even fiber-reinforced composites like carbon fiber nylon.

However, for more than two decades, FDM 3D printing has largely relied on fixed-size circular-shaped nozzles. Smaller nozzle sizes are great for achieving precision but print far too slowly to be viable for large parts, whereas larger nozzles offer throughput but lose out on geometric accuracy.

According to Sculpman, these tradeoffs are a result of the fixed output shapes of conventional nozzles, which produce layers of cylindrical material tracks. Since the contact area between these tracks is limited, printing clean-looking parts with adequate layer adhesion can be troublesome, calling for several nozzle types (small and large) that serve different purposes.

Gerolf Vanacker, co-founder of Sculpman, explains, “Cylindrical tracks that are placed horizontally next to each other produce a wave pattern. Even if they are squished slightly flat by the nozzle, the area where both tracks touch is still small, as each track’s cross-section is elliptic and only the mid-section of the sides touch.”

Sculpman’s Variable Nozzle Technology

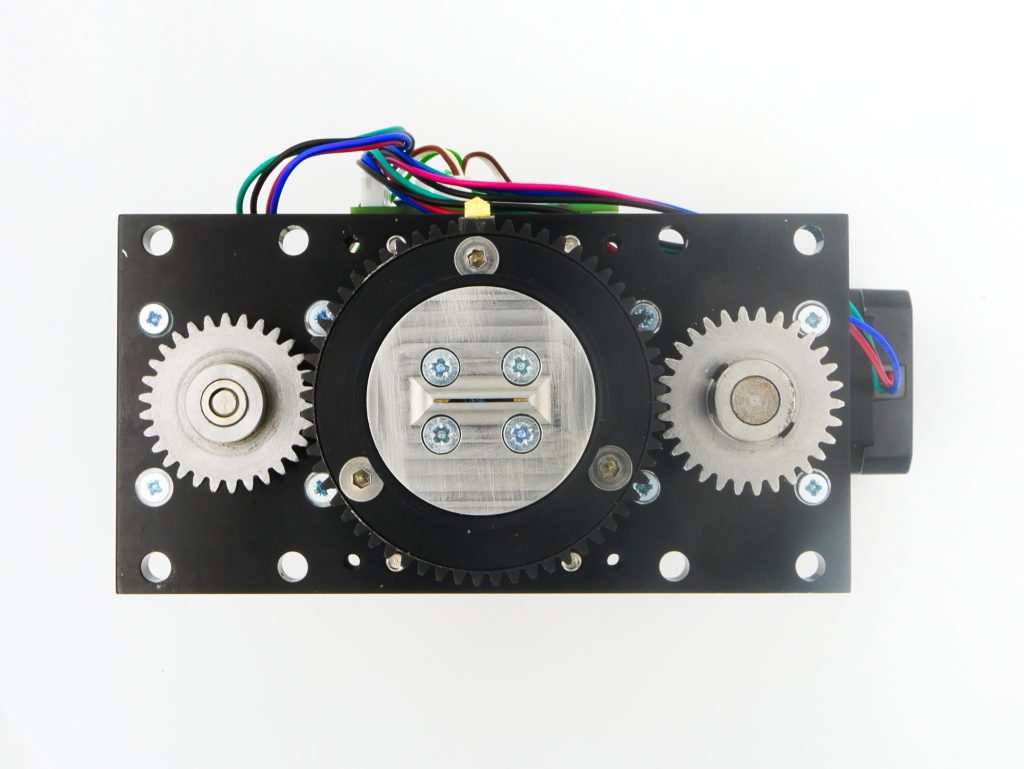

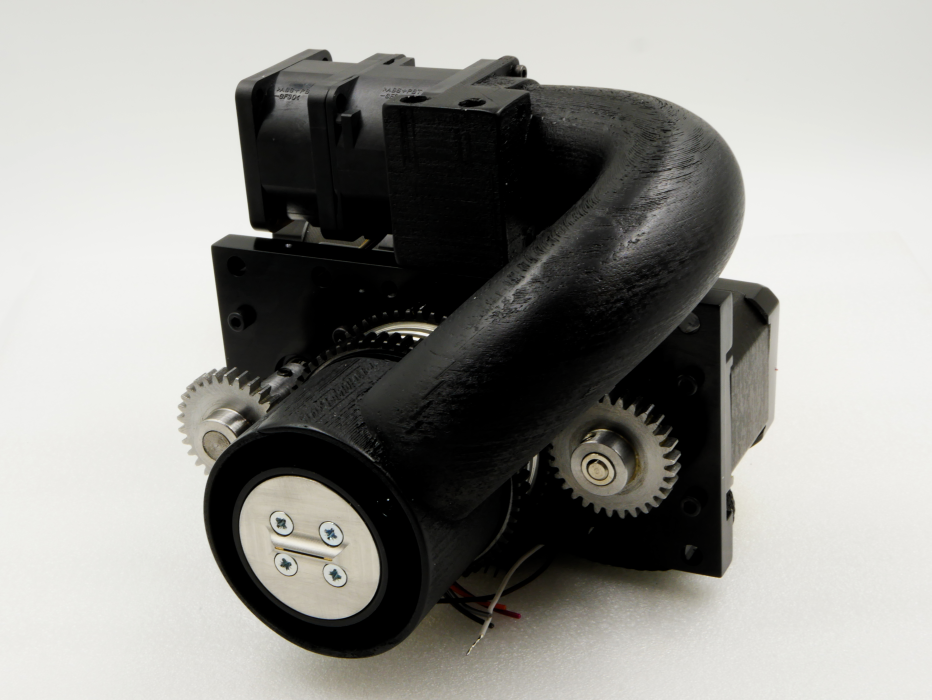

Intended as a jack-of-all-trades approach, Sculpman’s Variable Nozzle Technology eliminates cylindrical tracks and extrudes flat rectangular tracks of varying width instead. The nozzle itself features a rectangular opening capable of rotating infinitely to ensure it’s always perpendicular to the direction of travel, allowing for more flexibility in path planning while improving layer alignment and layer adhesion. The nozzle also houses two sliding elements that can continually change the size of the opening mid-build, almost like the aperture of a camera, and can even close it completely to cut off the material flow altogether.

“If you come to think of it, it’s very similar to painting a picture,” Vanacker adds. “If you need high detail, a small pencil is the better choice. However, if larger areas need to be filled in, you’d be better of using a broad brush.”

Sculpman’s hotend system will be made available in a 0 to 10mm opening configuration with a cross-section of 0.5mm, allowing for build rates of up to 500cm3 per hour. The current nozzle design will be compatible with 2.85mm filaments, with or without an extrusion drive subassembly. Sculpman is also in the process of working on a similar system for granular pellet-based feedstocks. The company’s Variable Nozzle Technology will be showcased at Formnext 2021 in Hall 11, Booth D11.

According to Vanacker, the firm intends to target machine manufacturers in the 3D printing industry, as opposed to end-use consumers. He concludes, “Basically, we’re open to companies that want to try out our technology and integrate it within their systems.”

Aftermarket 3D printer accessories can often be just as impactful on the outcome of a build as the 3D printer itself. Just last month, Xaar, a UK-based developer of inkjet printing technology, announced the launch of its latest printhead: the Xaar Irix. The device comes in two different variants, Core and Pro, with the latter being more suitable for demanding applications with a focus on print quality, including inkjet-based 3D printing.

Elsewhere, at the University of Maryland, researchers have designed a ‘morphing’ nozzle that enables users to 3D print customized parts with fiber-filled composites. Unlike conventional printheads, the team’s device features novel side actuators that allow it to change shape during printing, and effectively re-orientate a material’s fibers. Using their new nozzle, the scientists were able to tweak the swelling qualities of complex objects, potentially lending it biomedical or military applications.

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter, liking us on Facebook, and tuning into the 3D Printing Industry YouTube Channel.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the Sculpman variable nozzle. Photo via Sculpman.