Desktop 3D printer manufacturer UltiMaker has rolled out the latest model from its best-selling S-Series range: the UltiMaker S7.

UltiMaker’s first new S-Series since the merger of Ultimaker and MakerBot last year, packs an upgraded build plate sensor and air filtration capabilities, making it more accurate than its predecessors. Thanks to its upgraded bed leveling functionality, the S7 is also said to enable improved first-layer adhesion, in a way that allows users to print on its 330 x 240 x 300 mm build plate with greater confidence.

“Over 25,000 customers innovate with the UltiMaker S5 every day, making the award-winning machine one of the market’s most used professional 3D printers,” said UltiMaker CEO Nadav Goshen. “With the S7, we took everything our customers loved about the S5 and made it even better.”

Fused Filament Fabrication at UltiMaker

Even before its merger with ex-Stratasys subsidiary MakerBot in 2022, Ultimaker had already established itself a strong reputation for developing versatile desktop 3D printers. In 2018, the company launched the Ultimaker S5, which until the introduction of the S7, was its flagship 3D printer. Though initially designed for dual-extruding composites, the S5 has since benefited from several upgrades, including a Metal Expansion Kit that enables users to print with 17-4 PH stainless steel.

Over the last five years, the S5’s versatility has seen it adopted by a variety of leading brands, including Ford, Siemens, L’Oréal, Volkswagen, Zeiss, Decathlon, and more. On the application front, Materialise, has also managed to test the S5 in medical 3D printing use cases, while ERIKS has developed a workflow that’s capable of meeting food safety standards with the S5.

For its part, MakerBot was already a known quantity in desktop 3D printing as well. Ahead of its merger with Ultimaker, the company was best known for its METHOD products. As revealed in 3D Printing Industry’s METHOD-X review, the machines are capable of creating parts durable enough for end-use, and the likes of the Arash Motor Company now use them to 3D print bespoke hypercar components.

When Ultimaker and MakerBot first came together, it was announced that their businesses would pool resources to become a consolidated entity, and since the deal was wrapped up, the newly-merged UltiMaker has already launched the MakerBot SKETCH Large. That said, with the S7, the business is now offering a glimpse into where it intends to take the S-Series brand moving forwards.

UltiMaker’s new flagship 3D printer

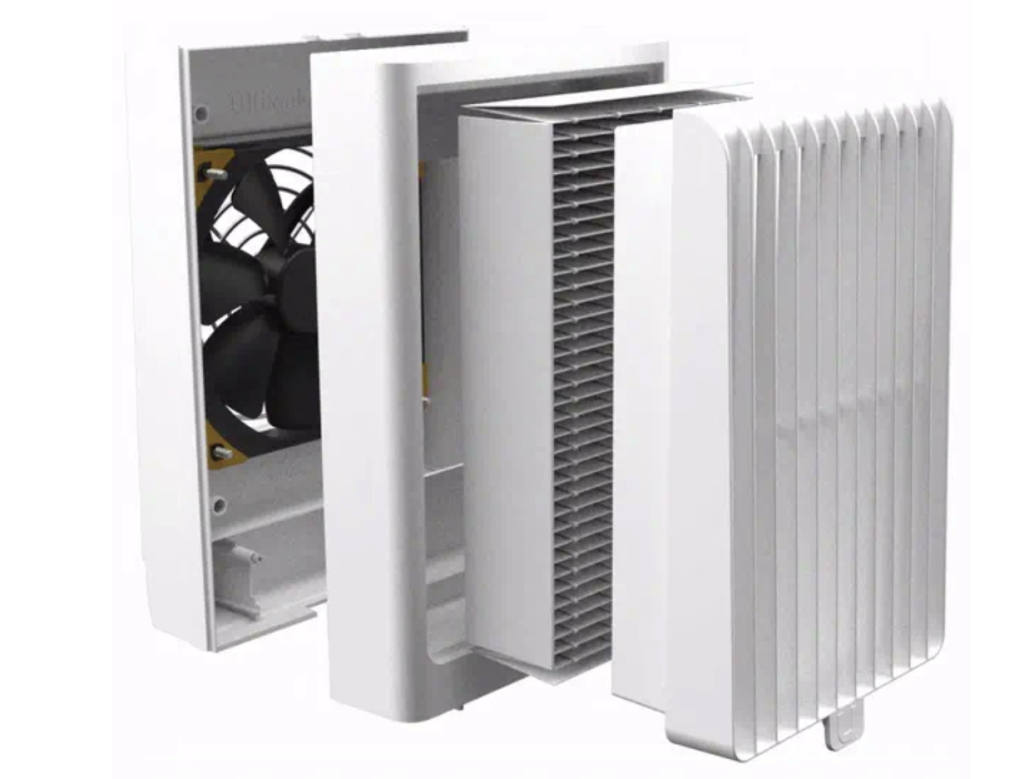

With the S7, UltiMaker has introduced a system that’s packed with new features, designed to make it both accessible and capable of reliably churning out parts. Headline additions include an inductive build plate sensor that’s said to probe the build area with less noise and greater accuracy. The system’s automatic tilt compensation functionality also means users don’t have to calibrate the S7’s bed with a thumbscrew, making the task of bed leveling less daunting to new adopters.

In another upgrade, UltiMaker has integrated a new air manager into the system, which in independent testing has proven capable of removing up to 95% of ultrafine particles from each print. This not provides users with peace of mind that air around the machine is being properly filtered, but thanks to its fully enclosed build chamber and single glass door, it also enables a boost in overall print quality.

Elsewhere, UltiMaker has fitted its latest S-Series unit with a PEI-coated flexible build plate that allows adopters to effortlessly remove parts, while avoiding the use of glue. What’s more, due to its whopping 25 magnets and four alignment pins, the bed can be quickly and precisely replaced, accelerating a task that can sometimes be a time sink.

So, how does the S7 stack up against the S5? Ultimaker has made a concerted effort to retain the best features of its predecessor in the S7. The firm’s new machine is not only backwards compatible, but it’s able to print with the same library of over 280 materials as before, and its upgraded capabilities are already said to have been tested in-house by polymer developers Polymaker and igus with glowing results.

“As more customers are using 3D printing to grow and innovate their business, our goal is to provide them with a complete solution to be successful,” added Goshen. “With the new S7, customers can be setup and running in minutes: managing printers, users, and designs with our Digital Factory software, improving their 3D printing knowledge with e-learning courses on the UltiMaker Academy, and choosing from hundreds of materials and plugins using the UltiMaker Cura Marketplace.”

Technical specifications and pricing

Below are the technical specifications for the UltiMaker S7 3D printer. At launch, pricing information hasn’t been made public, but those interested in acquiring the machine can contact UltiMaker for a quote here.

| Technology | Fused filament fabrication (FFF) |

| Build Volume | 330 x 240 x 300 mm |

| Feeder Type | Dual-gear Feeder |

| Filament Diameter | 2.85 mm |

| XYZ Resolution | 6.9, 6.9, 2.5 micron |

| Nozzle Diameter | 180 – 280 °C |

| Dimensions | 495 x 585 x 800 mm |

| Weight | 29.1 kg |

| Maximum Power Ouput | 500W |

| File Transfer | Wi-Fi (2.4 and 5 GHz), Ethernet, USB |

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the new UltiMaker S7 3D printer. Image via UltiMaker.