July 2023 was a month dominated by developments in additive manufacturing for space applications, the scalability of metal powder, and large format 3D printing.

Review all the 3D Printing Industry News from 2023.

The merger and acquisition saga between Stratasys, 3D Systems, Nano Dimension, and Desktop Metal also continued into July 2023. The month saw Nano Dimension increase its special tender offer price for Stratasys, as 3D Systems’ hoped for a swift termination of Stratasys’ merger agreement with Desktop Metal.

Read on for more 2023 3D printing news highlights from 3DCeram, Skyrora, Orbital Composites, PyroGenesis, 6K Additive, Q.Big 3D, KraussMaffei, and more.

Stratasys, 3D Systems, Nano Dimension, Desktop Metal saga continues

3D printing news surrounding the merger and acquisition efforts of Stratasys, 3D Systems, Nano Dimension, and Desktop Metal continued to dominate headlines in July.

The start of the month saw Nano Dimension’s Chairman and CEO Yoav Stern respond to a comprehensive update on the merger and acquisition activity published by 3D Printing Industry in June. In particular, Stern addressed the report produced by Lake Street Capital, which was quoted in the article.

Stern highlighted claims suggesting that “institutional investors do not support their attempt to acquire Stratasys,” as being completely inaccurate. Suggestions that past attempts to acquire Stratasys were not serious were also challenged by Stern, who stated that “when we tendered the first time at $18 at end of May 2023, the share was traded at less than $14 and it went up following our tender. Since then, we have increased it to $20.05.”

Stern’s comments were vindicated later in July when Nano Dimension increased its special tender offer price for Stratasys Ltd. shares. This increase was made in response to the prospect of a 3D Systems and Stratasys merger becoming more tangible.

Nano Dimension’s offer rose from $24.00 to $25.00 per share in cash, representing an increase that provided a 233% premium over the cash portion of 3D Systems’ offer, and a 93% premium over Stratasys’ share price. At the time, 3D Systems made a combined offer of $24.00 per Stratasys share.

However, despite the improved offer, Stratasys remained firm in advising stakeholders against the Nano Dimension partial offer. In a letter sent to Shareholders on July 17th, Yonah Lloyd, Stratasys CCO and VP of Investor Relations stated that Stern “cannot be trusted, has made misrepresentations about Stratasys and is not qualified to manage Stratasys.”

During this period, Stratasys announced that it considered 3D Systems’ merger proposal a ‘Superior Proposal’ to that of Desktop Metal. This decision followed the expression of a lack of support for the Desktop Metal merger by Stratasys’ shareholders.

3D printing to accelerate space exploration

The month opened with the 3D printing news that Edinburgh-based rocket manufacturer Skyrora had begun full-duration testing to qualify the updated design of its 3D printed 70kN rocket engine. Developed as part of the European Space Agency’s (ESA) Commercial Space Transportation Services and Support Programme, Skyrora’s rocket engines will be used for the company’s first commercial launch to orbit.

Also in space rocket development, French 3D printing OEM 3DCeram announced that it had been selected as an official supplier to space propulsion manufacturer ThrustMe. As part of the collaboration, ThrustMe is leveraging 3DCeram’s expertise in ceramic 3D printing to optimize the development and production of key propulsion system components.

Elsewhere, Orbital Composites (Orbital), an in-space manufacturing startup, was awarded a $1.7M contract from the US Space Force. This contract seeks to advance the development of in-space servicing, assembly, and manufacturing (ISAM) antennas. It is hoped that developments in this field will facilitate global access to broadband internet and clean energy, encouraging further space technology advancements in the future.

July 2023 also saw Orbital sign an MoU with Virtus Solis to build the first MW-scale Satellite-Based Cellular Broadband station. “Our Space Factories will leverage advanced robotics and autonomous systems to build high-performance antennas in space, reducing the cost by >100X,” commented Orbitals CTO and Founder Cole Nielson.

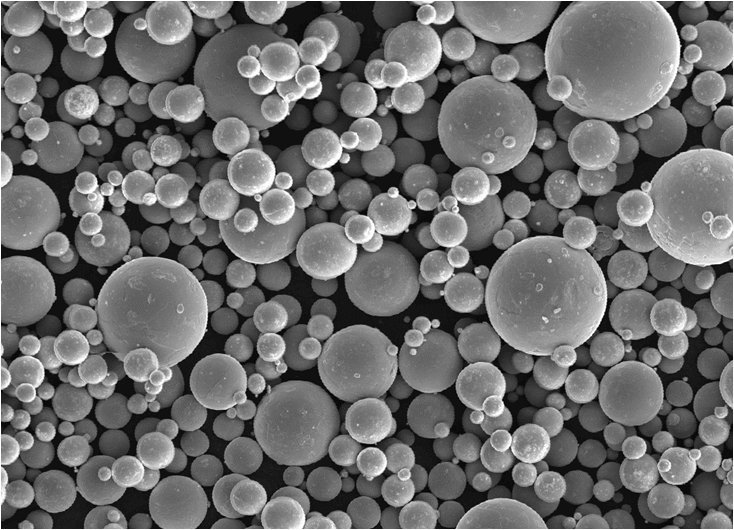

Development in Metal powder

Material developments in July centered around metal powders. The month’s biggest metal powder 3D printing news was that Montreal-based PyroGenesis received a commercial order for five metric tonnes (5,000 kg) of plasma atomized titanium metal powder used in 3D printing.

This is said to have been the first ever “by-the-tonne” order of titanium powder. The exact identity of the client has not been disclosed, however it is known that it is a US-based advanced materials company. The client also provisionally ordered an additional six tonnes (600 kg) of titanium metal powders. These orders will be fulfilled at PyroGenesis’ advanced production facility in Montreal, Quebec, Canada.

Industrial 3D printing materials manufacturer 6K Additive also moved to meet production demand for titanium powders through a partnership with French industrial metal 3D printing specialist Z3DLab. This collaboration is focused on the production of Z3DLab’s advanced ZTi titanium alloys range.

These powders will be produced using 6K’s proprietary UniMelt technology, which is said to deliver up to 100% yield. It is hoped that this collaboration will drive the production of new advanced 3D printing materials for use in medical implant and aerospace applications.

In material certification news, the Global standards organization ASTM International’s additive manufacturing technologies committee (F42) released a standard specification for maraging steel in powder bed fusion (PBF) 3D printing.

Maraging steel is a precipitate-hardened steel that gains strength through the aging heat treatment process and is widely used in the automotive, sporting goods, and aerospace industries. Titled ASTM F3607, this standard reportedly enables users to establish precise material requirements, whilst ensuring that their maraging steel parts possess their desired properties.

Advancements in large-format 3D printing

July also saw its fair share of 3D printer launches, especially with regard to large-format systems. For instance, German OEM KraussMaffei made its large-scale extrusion-based powerPrint 3D printer commercially available. First announced at last year’s K 2022 trade show, the powerPrint offers a substantial 2 x 2.5 x 2 m (10 m3) build volume, allowing for the production of large-scale parts for a variety of industrial applications.

The powerPrint incorporates a 350℃ extruder, making it compatible with a range of materials including PLA, PA, PET, PLA, ASA, TPU, and PP. KraussMaffei highlights molds, moldmaking, pipes and fittings, facade panels, and prototyping as key use cases of the powerPrint.

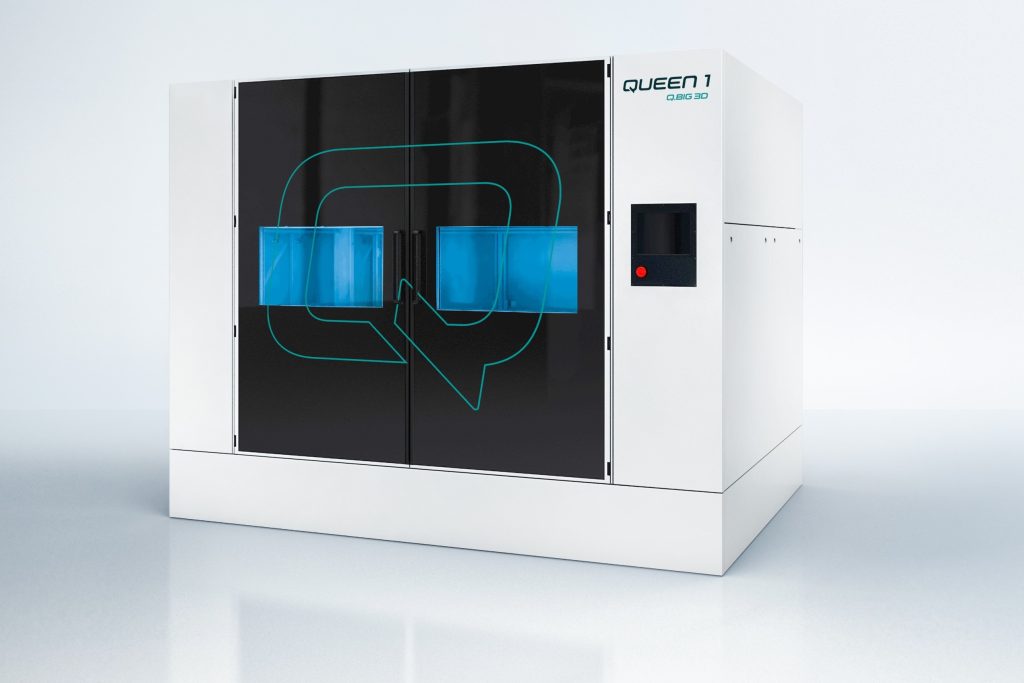

Elsewhere, Aalen-based large-format 3D printer manufacturer Q.Big 3D successfully raised €2 million in Series A funding to support the launch of the Queen 1 “XXXL” large-format 3D printer. Led by HZG Group, global engineering firm and long time Q.Big 3D investor Manz AG also backed the funding round.

The Queen 1 incorporates Q.Big’s Variable Fused Granular Fabrication (VFGF) process, and offers a substantial 1700 x 1050 x 1050 mm build size. Following this funding, the company announced that it would intensify its sales activity, with plans to start shipping the Queen 1 by the end of the year.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows the Skyrora 70 kN rocket engine. Photo via Skyrora.