3D printing software developer Ai Build has introduced a new program that allows users to finetune the 3D models of proposed prints using text prompts.

Designed to accelerate the creation of even the most advanced, multi-axis toolpaths via a single, intuitive user interface, Talk to AiSync simplifies the process by replacing manual coding with visual programming. For now, the firm’s software has only been made available to beta testing partners, but once the product’s kinks and boundaries have been worked out, it’s being earmarked for a wider release.

“A special thanks to my Co-founder Michail Desyllas who moved mountains to reach this breakthrough on time and on budget with his determination,” said Ai Build Co-founder Daghan Cam. “[It was a] massive team effort to unlock the full potential of additive manufacturing together with our partners and clients. We are only scratching the surface of the potential of generative AI.”

Ai Build arrives on the AM scene

Based in London, Ai Build is a Software-as-a-Service (Saas) company that specializes in developing 3D printing automation software. Since the firm was founded in 2015, Desyllas and Cam have sought to come up with a way of decisively eliminating the risk of human errors in additive manufacturing, and the need for extensive expertise to maximize the technology’s productivity.

According to the entrepreneurs, 3D printing enables the creation of lightweight parts from less material than traditional production methods allow. However, they also say the process is error-prone, limiting its deployment in safety-critical applications.

To get around this problem, Ai Build has developed a way of fully-automating additive manufacturing, from plan to print, and radically improving speed, quality, and scalability. In doing so, the company boasts of having created a tool for widening the technology’s applications, and it’s now working with partners to realize its potential.

Ahead of the Talk to AiSync’s full commercial launch, Ai Build has begun working with various industry stalwarts including Meltio, Weber Additive, Q5D Technology, CEAD, Massive Dimension, Dyze Design, and 2KM. As a result, the software is already being tested on machines based around solid-state, extrusion, and multi-axis robotic technologies, in a way that bodes well for its future compatibility.

How does Talk to AiSync work?

Talk to AiSync has essentially been built via the combination of Ai Build’s visual toolpath programming engine, and OpenAI’s large language model, GPT. Fed with years of real-world manufacturing data at the company’s AiLab, the technology allows users to make changes to 3D models via simple text inputs such as “slice the part with 2mm layer height.” or “raise the infill gradually in the last few layers.”

Though not designed to replace designers or engineers entirely, as human inputs are still very much part of the decision-making process when using the program, Ai Build says it “elevates the user experience.” In particular, the firm anticipates that the automation benefits of its program will “massively reduce barriers to entry” in 3D printing, by allowing new adopters to bypass costly trial and error.

Ai Build also says that Talk to AiSync’s accessible UI will empower engineers to “optimize production at superhuman levels,” by allowing them to focus on creating complex builds over mastering interfaces. Ultimately, as well as reducing average ‘design to production times,’ the company sees its technology addressing areas like sand casting, manifold, tooling, gripper, and mold production applications.

Those wishing to trial the software can contact Ai Build to request early access here.

AI-driven 3D printing technologies

As is the case in the consumer technology space, artificial intelligence (AI) is increasingly gaining traction as a means of automating often-laborious tasks. In R&D applications, AI-led machine learning algorithms have previously been developed by researchers at Lehigh University, which are capable of accelerating 3D printing material discovery.

At University College London (UCL), meanwhile, another team has managed to use AI and X-ray imaging to 3D print a lost Vincent Van Gogh painting. The researchers did so by feeding captured imaging data into an AI algorithm capable of extrapolating an artist’s style, which then created a 3D model of what the original might have looked like.

More recently, a team made up of engineers at five Fraunhofer research institutes have unveiled an AI-driven joint implant 3D printing workflow. The automated implant design process, in which AI is deployed to turn 2D X-ray images into 3D finger models, is said to not only enable the correction of finger positioning issues but facilitate the creation of frictionless parts, with reduced post-processing needs.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

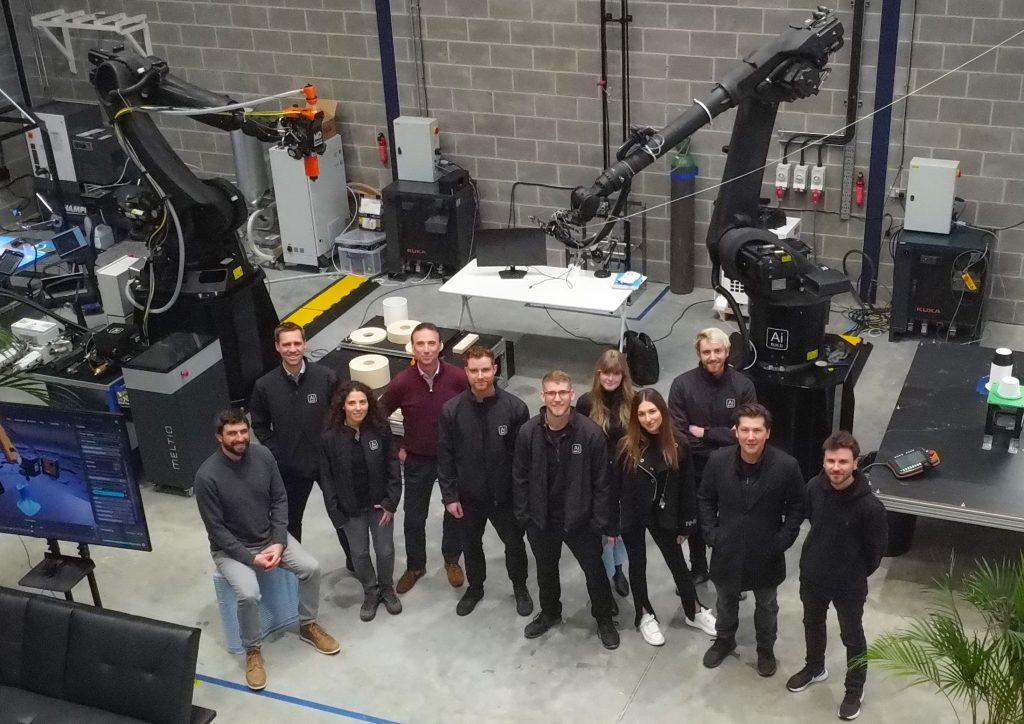

Featured images show engineers using Ai Build’s Talk to AiSync software. Photo via Ai Build.