At the end of 2023 3devo, a manufacturer of 3D printing material processing systems, announced plans to change its business model.

The company stated that it has moved away from a traditional sales model, and will no longer directly sell its 3D printing filament recycling technology.

Communicating the decision to stakeholders, partners, and clients, 3devo described this transition as a ‘bold step’ that will ‘deepen our impact and support’ for customer and partner projects.

The netherlands-based company has now provided clarity on what this new approach will look like. 3devo CEO Tim Wesselink has highlighted that, having ceased direct sales of equipment, the company will now offer a subscription-based “leasing model” where customers can rent equipment when they need it.

The company will also offer support to clients throughout all stages of their projects, specifically tailoring 3devo equipment to customer needs. 3devo will continue to provide existing customers with spare parts for purchased machines. What’s more, customers will still be able to purchase hardware through 3devo’s reseller channels.

Wesselink hopes that this new approach will “align customer success with our own success,” to enable 1 million 3D printing innovations by 2032. This new business model is also said to be more cost-effective for clients, mitigating the financial risks associated with 3D printing projects.

Customers can pay monthly or yearly for this offering, with a choice of three different subscription packages – Discovery, Core Project, and Advanced.

“We believe that we should be there to help a client along the way, to distribute the risk and the value evenly, because there’s quite a lot of risk that comes into play if you invest in a solution that you’re not completely sure is going to get you where you want to be,” stated Wesselink in the official announcement video.

“We believe as a company we should be carrying this responsibility together with our clients as a partner and taking steps together towards that goal.”

3devo’s 3D printing portfolio

Founded in 2016, 3devo produces hardware that enables users to recycle old material and create their own 3D printing filaments.

The company first entered the 3D printing market with the launch of the NEXT 1.0 and Advanced extruders. Both systems allow users to recycle unwanted 3D prints into new filament, yielding interesting material combinations in the process.

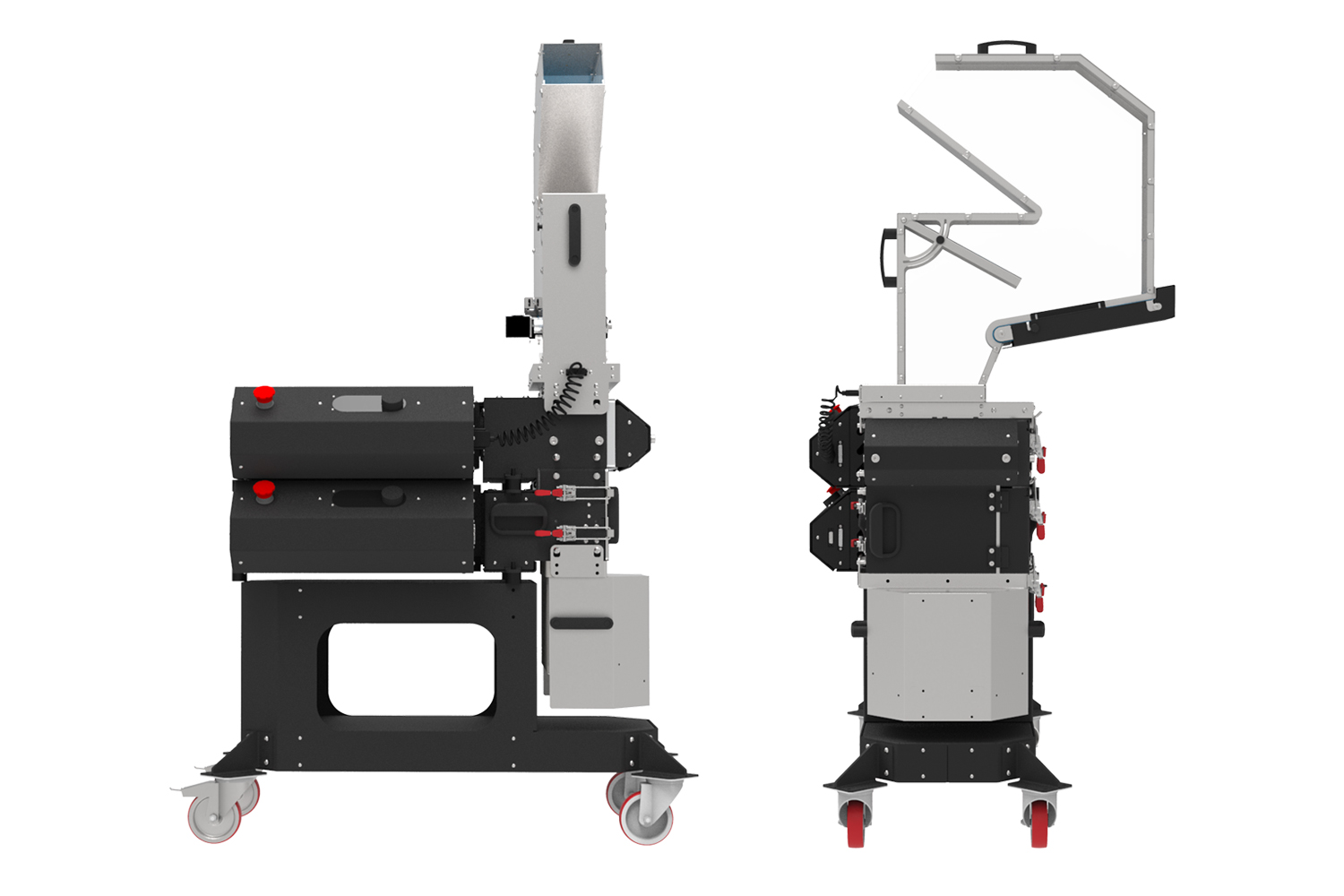

The company has since expanded its portfolio with the launch of the GP20 2-in-one Shredder Hybrid for recycling 3D printing plastics, as well as purging materials such as the DevoClean Midtemp EZ.

Most recently, the company launched the Filament Maker TWO at Formnext 2023. This upgraded system integrates advanced data insights, improved extrusion control, precision, and stability. The Filament Maker TWO is targeted towards technical teams, educational institutions, and public labs, thanks to its user-friendly design.

This new material processing system is available in two models – Fusion and HighFlow. The Fusion configuration is optimized for research and development applications, enabling material mixing and the creation of custom filaments. HighFlow is designed for production applications, providing a steady flow suitable for compound or virgin materials.

A new business model to align customer success

3devo’s new business model includes a phased approach to customer projects, offering close collaboration with clients to ensure its technology is well suited to project requirements. Initially, the company works with the client to evaluate the project, determine whether the aims are realistic, and outline how best these goals can be achieved.

There is no guarantee that a client’s project will be well suited to 3devo’s technology. “We want to be very clear and candid about what is possible for us to deliver and what’s not, to make sure expectations are balanced,” explained Wesselink. This initial stage requires relatively small financial and time commitments from both sides.

Next, 3devo offers customers a chance to assess its hardware options and determine which technology would work best within their project. This is achieved through workshops which 3devo can either hold in-house or on-site at the client’s location. Once hardware options have been determined, customers can then lease the equipment from 3devo.

According to 3devo, this model is risk free, with customers able to return equipment if it is not performing as hoped. Users can also return hardware once it is no longer required, saving money compared to if they had purchased the hardware outright.

3devo will also work to tailor hardware to meet specific customer requirements through co-development and co-creation. Moreover, 3devo’s Advanced support extends beyond project completion, to ensure long-term project success and evolution.

“The leasing model basically means that you can get access to the equipment in a way where you’re relatively free of failure, meaning that if you don’t reach your goal, you can send the equipment back. You’re not financially committed,” explained Wesselink. “If you’re done with your innovation, then the hardware comes back, and we can place it at a customer that does need it.”

Recycled 3D printing material – a growing market

Increasing the sustainability of 3D printing is a core concern within the industry, with material companies working to secure supply chains and minimize environmental impact by producing recycled products. A Life Cycle Analysis published by KIMYA last year reported that using recycled PETG filaments can reduce 3D printing CO2 emissions by up to 35%.

California-based industrial designer Reiten Cheng developed an open-source device that can turn discarded plastic bottles into functional recycled 3D printing filament. Called the ‘Polyformer,’ the parts of this modular machine can be 3D printed, allowing makers to easily fabricate their own filament recycling system. Cheng has also published a free step-by-step guide to building the Polyformer on GitHub.

Elsewhere, UK-based 3D printing filament manufacturer Filamentive offers a range of biodegradable and recycled filaments. Last year, the company launched its Economy PLA, made with up to 99.99% recycled materials. Advertised as a “potentially eco-friendly option” in the 3D printing filament market, Economy PLA is available in black and white colors.

“We are dedicated to sustainability and consistently seek ways to minimize our environmental footprint. The launch of Economy PLA is a significant step in this direction,” commented Ravi Toor, Managing Director, Filamentive. “We believe this product will resonate with customers seeking both sustainability and high-quality 3D printing filament.”

More recently, Carbon fiber material recycling specialist Vartega secured $10 million in equity financing to develop and promote its 100% recycled carbon fiber reinforced filament.

Vartega’s proprietary recycling process enables high-performance carbon fiber to be recovered and converted into advanced 3D printing materials. The company hopes to further integrate its recycled material with industry partners in the additive manufacturing, automotive, consumer electronics, and sporting goods sectors.

Subscribe to the 3D Printing Industry newsletter to keep up to date with the latest 3D printing news. You can also follow us on Twitter, like our Facebook page, and subscribe to the 3D Printing Industry Youtube channel to access more exclusive content.

Are you interested in working in the additive manufacturing industry? Visit 3D Printing Jobs to view a selection of available roles and kickstart your career.

Featured image shows a 3devo engineer working on a Filament Maker TWO. Photo via 3devo.