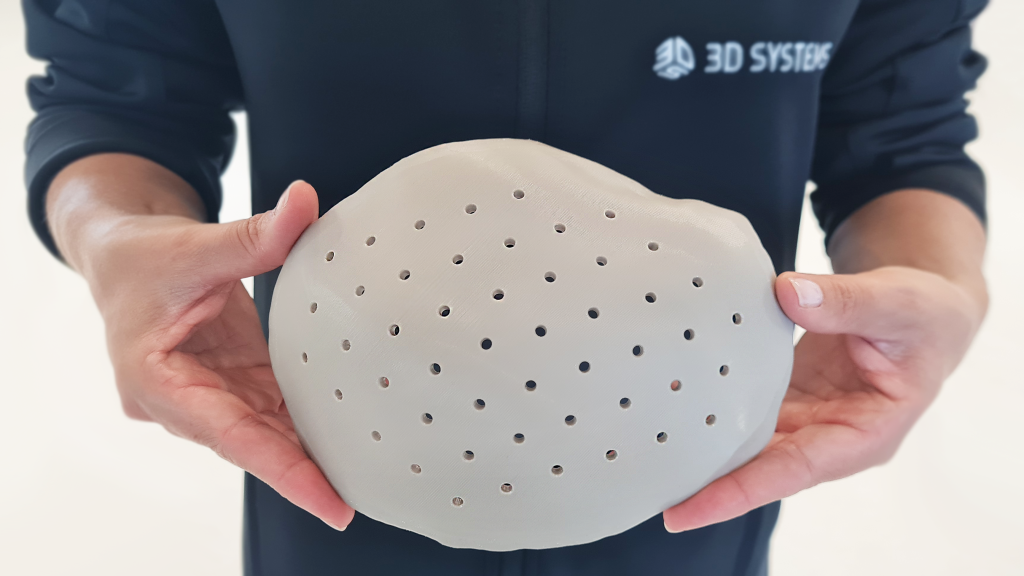

3D printer manufacturer 3D Systems has secured FDA 510K clearance for its 3D printed, patient-specific VSP polyetheretherketone (PEEK) Cranial Implant solution.

The VSP PEEK Cranial Implant’s ability to address skull defects in cranioplasty stems from its fully FDA-cleared workflow. This comprehensive system integrates segmentation and 3D modeling software, the 3D Systems EXT 220 MED 3D printer, and Evonik VESTAKEEP i4 3DF PEEK material, all within a pre-defined production process.

Possessing exceptional biocompatibility and resistance to bodily fluids, PEEK (a high-performance polymer suitable for implantation) has become a leading choice in medical devices due to its mechanical properties that mirror those of human bone. Additionally, its stability across various temperatures and inherent radiolucency further solidify its position, allowing for clearer evaluations during medical imaging.

“Receiving FDA clearance for our VSP PEEK Cranial Implant solution is a significant milestone in our journey. Our EXT 220 MED printing system has already enabled the production of nearly 40 cranial implants in support of successful cranioplasties throughout Europe. With this FDA clearance, we are now able to bring VSP PEEK Cranial Implant to the U.S. — setting a new standard of excellence for these procedures. We are now looking to the next applications for this technology, which includes 3D-printed spine interbody fusion implants, carbon fiber-reinforced PEEK for plating applications in trauma and fixation, and bioresorbable polymers for large bone and craniomaxillofacial applications,” said Dr. Gautam Gupta, SVP & General Manager, medical devices, 3D Systems.

Faster patient care through 3D printing

This FDA clearance enables 3D Systems to significantly expand its PEEK product portfolio through the EXT 220 MED platform. According to the company, AM helps create patient-specific cranial implants using up to 85% less material compared to traditional machining, saving costs for expensive implantable PEEK.

The printer’s cleanroom design and simplified post-processing enable faster turnaround of patient-specific medical devices directly at hospitals, keeping costs controlled. Additionally, this solution has facilitated nearly 40 successful cranioplasties in Switzerland, Austria, and Israel. 3D Systems aims to speed partner development by leveraging its PEEK implant expertise and EXT 220 MED platform. This aids partners in navigating regulations efficiently, ensuring swift access to medical solutions for improved patient care.

For over a decade, 3D Systems has collaborated with surgeons, planning over 150,000 patient-specific cases. It also claims to have produced over two million implants and instruments for over 100 CE-marked and FDA-cleared devices. These are manufactured in its world-class, FDA-registered, ISO 13485-certified facilities located in Littleton, Colorado, and Leuven, Belgium, says the company.

3D printed cranial implants

As per a February 2023 report from Acumen Research and Consulting, the cranial implants market was valued at approximately $1.2 billion in 2021. 3D Systems, citing the same report, foresees it reaching nearly $2.1 billion by 2030.

Notably, the use of 3D printed cranial implants can be traced back to 2014 when Slovakian company CEIT Biomedical Engineering gained approval to use 3D printing to create individually tailored cranial implants. Partnering with EOS, CEIT utilized a biocompatible titanium alloy to produce implants with complex geometries. CEIT successfully implanted a custom cranial implant in a patient, leading to improved mobility and communication.

On another note, Apium Additive Technologies achieved a milestone in medical PEEK 3D printing, by meeting biocompatibility standards for skull and hand implants. Utilizing VESTAKEEP i4 G resin, the filament ensures long-term implant durability and x-ray transparency. This advancement promises to enhance patient-specific implant production, offering high-performance materials, while also reducing lead times and costs, and enabling on-site manufacturing in hospitals. Apium’s FFF printing facilitates organic geometries with low thermal conductivity, potentially improving patient comfort.

Last year, by employing its point-of-care additive manufacturing solution, 3D Systems produced a patient-specific 3D printed cranial implant for a procedure at University Hospital Basel. This marks the first compliance with current Medical Devices Regulations (MDR) for a cranial implant 3D printed at the point of care. Fabricated on the hospital’s 3D Systems’ EXT 220 MED extrusion platform, the biocompatible implant was created using PEEK material.

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows the VSP PEEK Cranial Implant is the first FDA-cleared, additively manufactured PEEK implant intended for cranioplasty procedures to restore defects in the skull. Photo via 3D Systems.