Automated post-processing system manufacturer PostProcess has published the findings of its 2022 Post-Printing Trends Survey.

The results of PostProcess’ fourth annual survey reflect a growing manufacturer demand for ways of better dealing with labor shortages and meeting their sustainability goals. In terms of post-processing, the firm has also identified a trend towards secondary processes, as well as rising concern among the users of production-scale technologies, about the suitability of current offerings to meet their scaling needs.

“I often hear post-processing referred to as the ‘dirty little secret’ in additive manufacturing, but it doesn’t need to be,” said Melissa Hanson, CMO of PostProcess. “We are excited to continue our mission of bringing this critical step in the overall 3D printing workflow to the forefront and spearhead the analysis of post-processing trends, which comes with much anticipation and is essential to growing the rapidly evolving additive industry.”

What is the Post-Printing Trends Survey?

For the last four years, PostProcess has asked the users of post-processing systems for their feedback via its annual industry-wide survey. Utilizing the resulting data, the firm has then made a habit of putting together market-segmented reports, which show how 3D printed parts are most commonly finished, in addition to how metrics like post-processing costs and lead times continue to change.

Previous PostProcess surveys have already proven very insightful, uncovering the relationship between resin removal and surface finishing, as well as 3D printing’s volume manufacturing trend. Building on these findings, this year’s survey has yielded an even deeper analysis, revealing other key trends, and the company believes it’ll “serve an integral resource” for mapping a rapidly evolving sector.

The basis for 2022’s report is also stronger than ever, with 34% of respondents having used 3D printing for a decade or more, twice as many as last year. In terms of demographic, 83% of contributors came from the US and Europe, while 9% are now operating in the APAC region (up from 0% just two years ago), and the top three participating sectors were medical, machinery and manufacturing.

Uncovering post-processing challenges

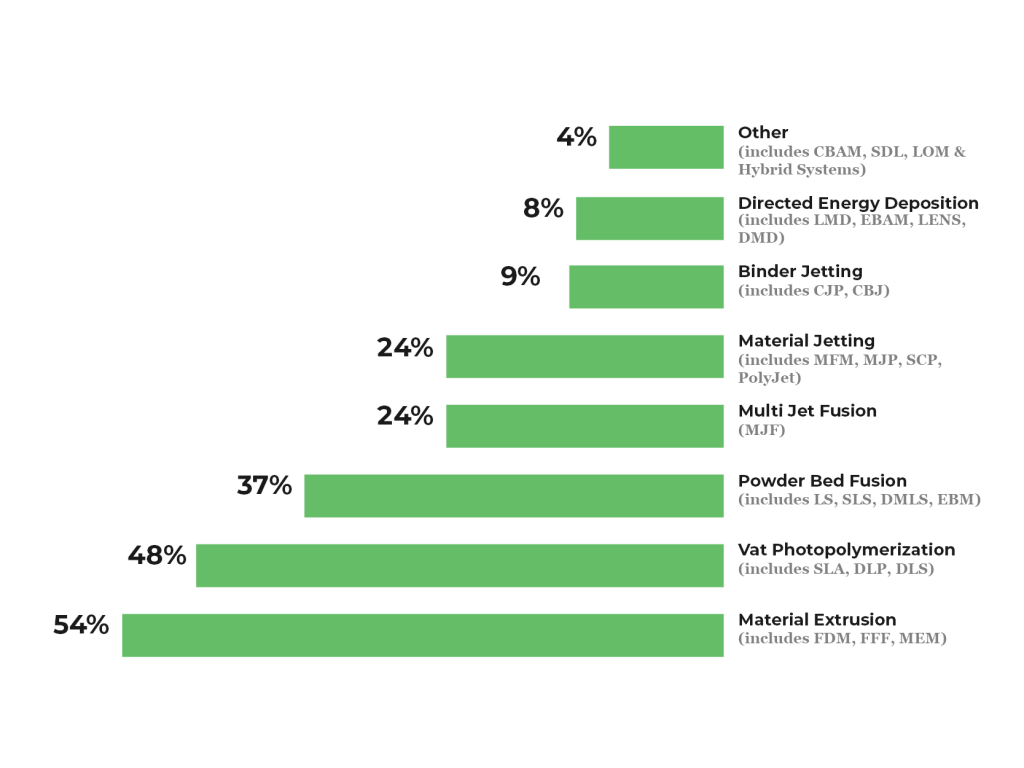

When it comes to the main 3D printing technologies adopted by users, PostProcess found no change against last year, with material extrusion proving the most popular. Interestingly, however, this year’s report identified a shift towards end-production applications in vat polymerization and powder bed fusion (PBF), the users of which made up 48% and 37% of respondents respectively.

On a recent webinar arranged to publicize the report’s findings, it was also revealed that the number of manufacturers using two or more print technologies has stabilized at around 50%, coming in this year at 57%. According to one of the session hosts, the firm’s VP of Strategic Partnerships Dean VonBank, this is happening due to users trying technologies, but “as they move to production, focusing on one or two.”

Elsewhere, PBF adopters said the challenges they face have shifted as well. Two years ago, PostProcess’ report found that such users were primarily concerned about labor costs, damaged parts and throughput. Now they’re not only dealing with staffing issues, but increasingly showing environmental and waste management concerns. VonBank added that PBF users are likely “trying to find the right labor” to implement production-scale workflows, and targeting those able to do so efficiently.

On the post-processing side of its survey, PostProcess found that the same three technologies remained the most-used: support removal (54%), resin removal (42%) and surface finishing (39%). While this has remained unchanged over all four iterations of the firm’s report, VonBank said the firm is now seeing “secondary processes cropping up” like vapor smoothing, dyeing and curing, as “people look for things that can get them an even better part than they’ve seen in the past.”

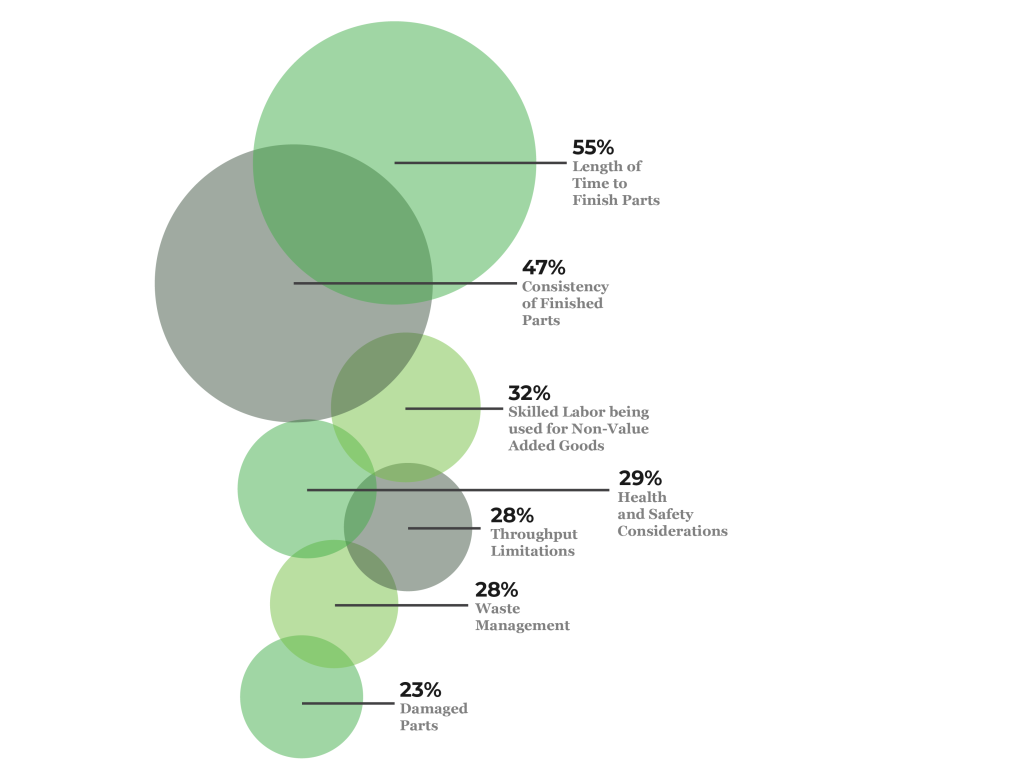

More broadly, the report has also highlighted some of the ongoing challenges facing the users of post-processing systems. For a third year in a row, the length of time required to finish parts was respondents’ number one gripe (55%), with consistency being deemed the second biggest issue (47%) faced by those treating 3D printed products.

Lastly, when asked if current post-processing methods contribute or inhibit their 3D printing goals, the majority of contributors said they remain acceptable or challenging today. Users of production-oriented technologies like PBF, material jetting, vat polymerization and Directed Energy Deposition (DED), also identified part finishing as an issue that could become more of a bottleneck in future, as they scale.

PostProcess Technologies encourages anyone who currently utilizes or is interested in additive manufacturing to sign up to receive a full copy of the 2022 Post-Printing Trends Report here.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? featuring discussion, debriefs, video shorts and webinar replays.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows a mock-up of an iPad accessing PostProcess’ annual survey. Image via PostProcess.