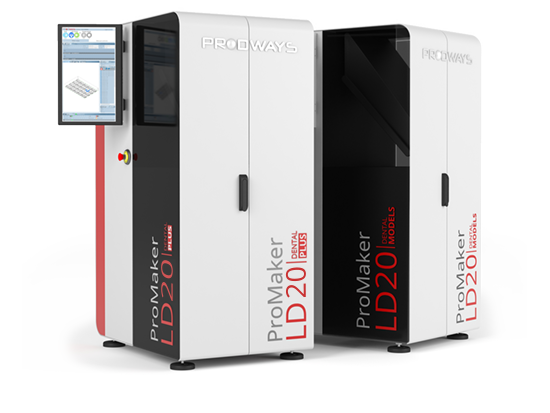

Ceramic company SINTX Technologies (SINTX) and Prodways have announced a partnership to develop a comprehensive solution for ceramic 3D printing.

Under this agreement, SINTX and its subsidiary, Technology Assessment and Transfer, Inc., will supply Prodways with ceramic-filled printable materials, aiding in process development and customer support. The objective of this collaboration is to establish a comprehensive workflow for the creation of advanced ceramic products, with a specific focus on casting applications.

Ann Kutsch, General Manager of the SINTX-Maryland site, said, “Our outstanding engineering team has 6 years of experience working with Prodways printers, and we have already used their equipment to commercialize multiple resin compositions and part designs. I expect that a more formal partnership will lead to some breakthrough developments and novel solutions for all our customers.”

Next-generation ceramics production

Dating back to 2018, SINTX has been actively engaged in ceramic 3D printing with the Prodways L5000. With this latest alliance, SINTX anticipates integrating the latest hardware innovations from Prodways into its operations.

According to the company, Prodways stands to gain significant advantages by tapping into SINTX’s Silica and Alumina-qualified slurries, available on the newest MovingLight machine generation. This machine is specifically designed for demanding ceramic applications, offering both high resolution and a versatile build envelope. Its flexibility in build envelope configuration and emphasis on process-oriented parameter control ensure scalability.

Having begun printing components in 1998, SINTX has seen its capabilities expand from prototyping and small-scale production to a more established production process. Currently, SINTX offers a variety of 3D printed ceramic parts made from materials like alumina, zirconia, and silica. It also provides custom printable ceramic resin mixtures to clients in various industries. One of its latest developments was the company’s multi-year supply agreement with a major aerospace company announced in February 2024.

The versatility of ceramic 3D printing

Ceramic 3D printing offers benefits such as producing complex shapes, facilitating rapid prototyping, and working with various materials. Despite challenges such as parameter optimization and post-processing requirements, ceramic 3D printing holds immense potential for innovation in diverse industries.

For instance, researchers at Skolkovo Institute of Science and Technology (Skoltech) employed a 3D printing method to create a complex ceramic component for eco-friendly solid-oxide fuel cells (SOFCs). Utilizing micro-stereolithography technology and a standard office projector, they crafted the SOFCs with a new hierarchical lattice structure, enhancing ionic conductivity for maximum power output. Highlighted in the journal Ceramics International, this research opens avenues for cleaner energy solutions, but the broader adoption of such technology may face challenges due to geopolitical issues, as evidenced by the US Department of the Treasury‘s sanctions on Skolkovo entities in 2022.

On another note, Jiangnan University scientists developed a novel technique for 3D printing complex ceramic structures without support. Published in Nature Communications, the method utilizes a combination of direct ink writing (DW) and near-infrared (NIR) light-induced photopolymerization, allowing in-situ curing of multi-scale ceramic filaments. Involving pressure-assisted extrusion followed by NIR laser curing, this process enables the creation of ceramic structures without the need for support, holding promise for industries such as machinery, electronics, and aerospace.

Elsewhere, Cornell University, Dimensional Energy, and Austrian Ceramic 3D printing company Lithoz collaborated on a grant-funded project to develop innovative ceramics for 3D printing clean energy reactor components. With $50,000 in funding, researchers focused on creating a ceramic capable of withstanding high temperatures in thermocatalytic reactors. Through 3D printing and computer modeling, they aimed to layer this material into structures designed to enhance resilience and CO2 conversion rates in reactors.

Join the Expert Committee for the 2024 3D Printing Industry Awards to help select the winners!

What 3D printing trends do the industry leaders anticipate this year?

What does the Future of 3D printing hold for the next 10 years?

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter, or like our page on Facebook.

While you’re here, why not subscribe to our Youtube channel? Featuring discussion, debriefs, video shorts, and webinar replays.

Featured image shows 3D printed prototype medical ceramic parts. Photo via SINTX.